For more than a century, welding has been used to join pieces of metal together. In recent years, it has also been used on thermoplastics. It is one of the most reliable ways of achieving a strong, neat connection between two pieces of material.

Welding is a relatively simple process and one that you can probably picture even if you have never done it yourself. However, there are actually several types of welding, some of which are easier to learn than others. Some techniques immediately achieve a neat finish while others require some extra work to smooth out.

To help you find the right technique for the job, this article will introduce nine different welding methods. This includes looking at the pros and cons of each welding type.

Key Takeaways

- Welding is a method used to join materials, such as metals and thermoplastics, using intense heat to melt and fuse them together.

- There are various types of welding techniques, including TIG, MIG, and Stick welding, each with different applications and skill levels required.

- Some welding methods are more suited for specific materials or industries, such as TIG welding for steel and plasma arc welding for aerospace.

- Proper safety equipment, like safety glasses, welding helmets, and gloves, should always be used when welding to protect against potential hazards.

What Is Welding?

Welding is a method of joining materials together by using intense heat to melt parts, leading to them fusing into one piece when they cool. Historically, welding was only used to join pieces of metal together but it can also be used on thermoplastics.

Welding differs from methods of joining metal at lower temperatures, such as brazing and soldering, as these techniques don’t melt the base material itself.

Types of Welding Explained

This article explores nine welding methods, which sounds like a lot. However, there are actually more than 30 different ways to weld! If you familiarize yourself with these nine methods, you should always have the right technique for a welding job.

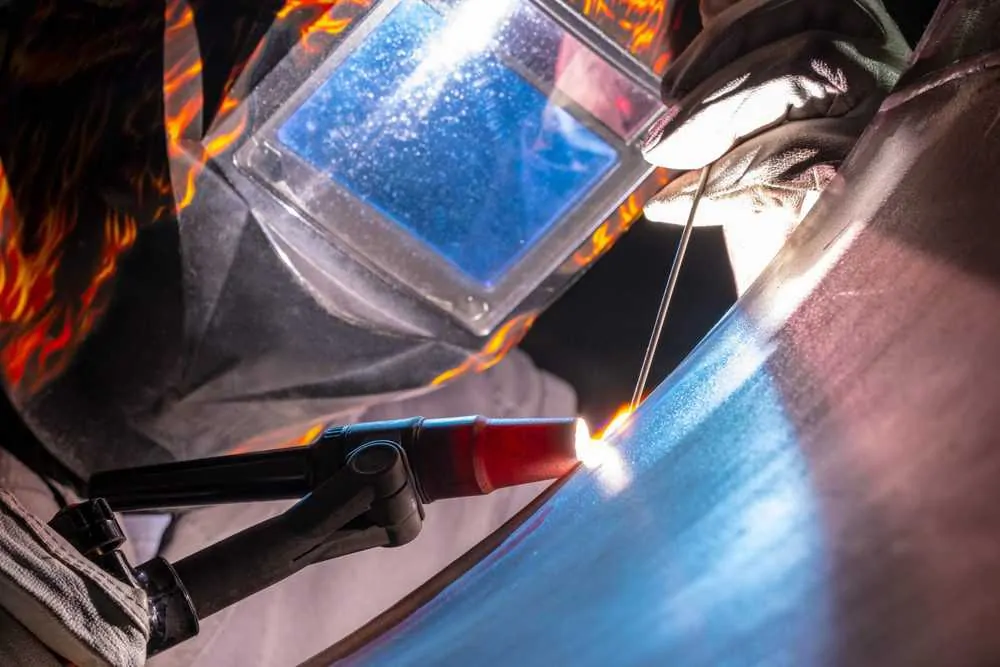

1. Gas Tungsten Arc Welding (TIG/GTAW)

Gas tungsten arc welding, or TIG welding as it is commonly known, is one of the few types of welding that doesn’t require a filler metal. You can add a filler if you prefer but feeding it by hand requires skill and patience. TIG welding is possible because the electrode is non-consumable and made of tungsten, so it won’t melt during the welding process.

This technique requires a constant gas supply to protect the weld, usually from a gas tank or can. In skilled hands, TIG welders provide a neat, smooth finish that doesn’t require any extra cleanup. For this reason, this method is usually used by highly skilled welders and professionals.

TIG welding is used extensively in the automotive and aerospace industries as it provides very strong, precise connections.

Pros

- Clean welds

- A high degree of control for the welder

- Possible with or without filler material

- Can be used manually or automatically

- Super-strong welds

Cons

- Requires a constant gas supply

- Unsuitable for outdoor use

- Requires a high degree of skill

- Time-consuming

- Not suitable for thicker metal joints

Product Specs

| Weld material | Copper, stainless steel, brass, bronze, aluminum, and nickel alloys |

| Energy source | Gas (chemical) |

| Skill level | Advanced |

| Applications | Industrial, shipbuilding, construction, automotive |

2. Flux-Cored Arc Welding (FCAW)

Flux-cored arc welding, or FCAW, is similar to MIG welding, which is why MIG welders can usually be used for both types. The flux core wire and filler metal are fed through the wand. Unlike TIG welding, which requires a gas supply, FCAW welds a core of flux around the electrode that creates a shield of gas around the weld, so you won’t need a gas feed.

FCAW is ideal for heavy-duty welding and thicker materials, so it is often used for plant and heavy machinery repairs. As there is no gas supply, dedicated flux core welders are usually cheaper and suitable for use outdoors.

It is primarily used in railroad construction, shipbuilding, manufacturing plants, and industrial pipe maintenance and repairs.

Pros

- Suitable for thicker joints

- Flexible torch movement and orientation

- Beginner-friendly

- Excellent weld penetration

- The highest metal deposition rate

Cons

- Creates slag

- Fixed-core wires are expensive

- Rougher weld finish

Product Specs

| Weld material | Copper, stainless steel, brass, bronze, aluminum, and nickel alloys |

| Energy source | Gas (chemical) |

| Skill level | Advanced |

| Applications | Industrial, shipbuilding, construction, automotive |

3. Stick-Shielded Metal Arc Welding (SMAW)

Stick welding is a traditional form of welding that has been in use since the 1930s. It is easy to use but creates an imperfect weld that will require some cleaning up to give it a smooth finish. The electrode stick is consumable, melting as the arc is created to form the filler metal and solidifying to create the bond between the metals.

Like FCAW, the stick is coated in flux to protect the weld, creating a cloud of gas to prevent oxidation. As the metal cools, the gas settles on the surface and forms slag.

Stick welders are suitable for use indoors and outdoors in any weather conditions. As it works on damaged and rusted surfaces, it is an excellent technique for equipment repairs.

Pros

- Works in all weather conditions

- Easy to master

- Great for intricate welding

- Doesn’t require a gas supply

Cons

- Leaves a rough finish

- Releases fumes

- The stick will need to be replaced, forcing breaks

- Metal deposition rates are low

Product Specs

| Weld material | Carbon steel, stainless steel, low alloy steel, and iron |

| Energy source | Electric arc (electrical) |

| Skill level | Beginner |

| Applications | Manufacturing, railroad, construction, automotive |

4. Gas Metal Arc Welding (MIG/GMAW)

MIG welding is one of the simplest methods, which makes it very beginner friendly. MIG stands for Metal Inert Gas and this method feeds the filler through the wand, while a constant gas supply creates a shield to protect the weld from the elements.

This isn’t the best technique for outdoor use but it is versatile and MIG welders are effective on many different types of metal. The filler wire is fed from a spool and acts as the electrode. This means MIG welding is very efficient as you only need to take breaks when the spool needs replacing.

MIG welding is widely used in the automotive industry, construction, and high-production manufacturing.

Pros

- Continuous welding

- Higher welding speeds

- Higher deposition rates

- Neater weld results

- Beginner-friendly

- Easily automated

Cons

- Higher setup costs

- Releases volatile gasses

- Higher maintenance costs

- Radiation effects are more severe

Product Specs

| Weld material | Steel, alloys, magnesium, and mild steel |

| Energy source | Gas (chemical) |

| Skill level | Beginner |

| Applications | Workshops, production lines, factories |

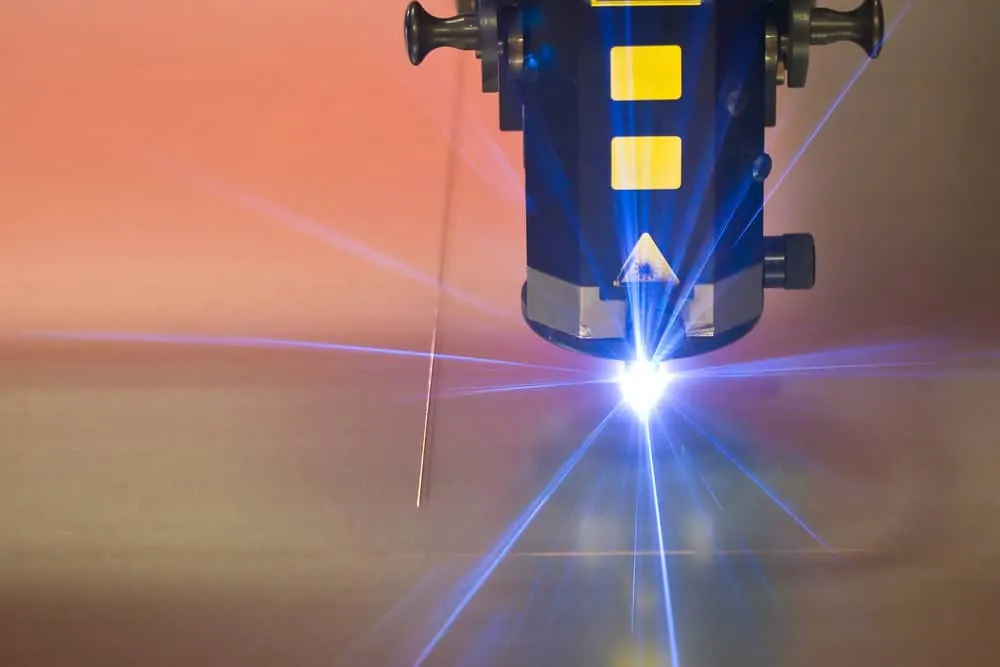

5. Laser Beam Welding

Laser beam welding is primarily used in industrial settings because it is easier to automate with robotics. It uses a super hot laser to melt the base metals and is effective on carbon steel, stainless steel, aluminum, and titanium. Laser beam welding is suitable for mass manufacturing, including the automotive industry.

Pros

- Easily automated

- More accurate

- Higher-strength weld

- Faster production rate

- Doesn’t require breaks to replace electrodes

Cons

- Unsuitable for manual welding

- Expensive initial setup

- Best used by automated robots

Product Specs

| Weld material | Carbon steel, aluminum, and stainless steel |

| Energy source | Laser beam |

| Skill level | Advanced |

| Applications | Manufacturing, automotive, prefabrication |

6. Electron-Beam Welding

Electron beams generate heat via kinetic energy. A high-velocity beam of electrons melts the base metal, which then fuses together as it cools. This process is highly sophisticated, automated, and expensive. It is only possible in a vacuum environment.

Pros

- Efficient

- Neat finish

- Precise

- Fast

- Continuous production

Cons

- Expensive to set up

- Highly complex

- Not suitable for manual welding

- Requires a vacuum environment

Product Specs

| Weld material | Steel, iron, stainless steel, and steel alloys |

| Energy source | Electron beam |

| Skill level | Advanced |

| Applications | Aircraft, nuclear, aerospace, defense, medical, oil, gas |

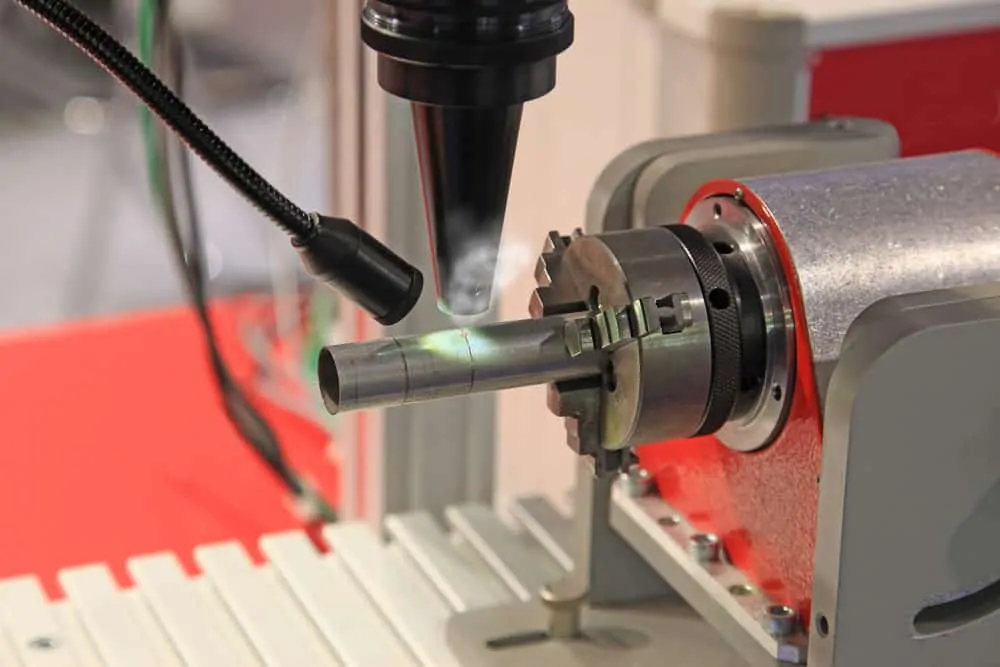

7. Plasma Arc Welding

Plasma arc welding is similar to TIG welding but uses higher temperatures in a smaller arc. This makes it more precise and means it is better suited for intricate welding. It works by pressurizing the gas inside the wand to create plasma. The plasma is then ionized to make it electrically conductive.

This results in an incredibly high temperature from the arc and means the base metals can be welded without using a filler metal. This method is very precise, allows for deeper weld penetration, and leaves a neat and satisfying weld.

Plasma arc welding is widely used in the aerospace and electronics industries.

Pros

- Low power consumption

- Deeper weld penetration for thicker materials

- Higher welding speeds

- Steady arc

Cons

- Expensive initial setup

- Noisy

- Requires a high degree of skill

- Higher radiation levels

Product Specs

| Weld material | Steel, stainless steel, iron, aluminum, and steel alloys |

| Energy source | Electric arc (electrical), Gas (chemical) |

| Skill level | Advanced |

| Applications | All commercial-grade metals |

8. Atomic Hydrogen Welding

Atomic hydrogen welding is a method that generates extreme heat, often at temperatures exceeding those of an acetylene torch. It uses hydrogen gas to shield two tungsten electrodes, and the intense heat means a filler metal is not required to achieve a strong fusion between the materials.

This is an older form of welding that has largely been replaced by MIG welding. It is used for tasks where rapid welding is needed and it works well on stainless steel and non-ferrous metals.

Pros

- Very fast results

- Extreme temperatures

- Efficient

- Less distortion

- No filler metal is required

Cons

- Higher running costs

- Only welds flat positions

- Dangerous temperatures

- High level of skill required

- Hydrogen is extremely flammable

Product Specs

| Weld material | Stainless steel, tungsten, and all ferrous and non-ferrous metals |

| Energy source | Hydrogen gas (chemical) |

| Skill level | Advanced |

| Applications | Automotive, construction, heavy-duty applications |

9. Electroslag

Electroslag is an advanced automated welding method. It joins the thin edges of two metal plates together vertically. The weld is made between the joints instead of on the outside. As a copper electrode is fed through a consumable guide tube, it acts as a filler metal.

Electricity creates the arc and the weld moves from the bottom of the seam, rising to the top and creating a seal. This type of welding is popular in the prefabricated steel industry because it welds thick pieces effectively.

Pros

- Automated

- High production rate

- Low slag production

- High deposition rate

- Heavier sections can be welded with a single pass

Cons

- High temperatures require constant cooling

- Slow cooling rate

- High setup costs

- Requires a high degree of skill

Product Specs

| Weld material | Carbon steel, high-strength steel, low-alloy steel, stainless steel, and aluminum |

| Energy source | Electric arc (electrical) |

| Skill level | Advanced |

| Applications | Prefabricated structures, production lines, factories |