Flux-core wire is the best material to use when welding dirty or rusty steel. It also makes welding outdoors possible.

The best flux-core wire improves the tensile strength of the weld and helps to bond metal to metal in difficult circumstances.

- Made from strong mild steel

- 0.030-inch gauge

- Can spot weld

- Low spatter

- High tensile strength

- Made of mild steel

- High tensile strength

- Vacuum-sealed packs

- Useful for multi-pass welding

- Made of carbon steel

- High manufacturing standards

- Non-porous

- 0.035-inch diameter

- 10-pound spool

- Better penetration

- Ideal for dirty & painted material

- All-position wire

- Welds carbon steel

Review Methodology: At Sensible Digs, we empower you with reliable insights derived from rigorous analysis and hands-on experience with flux-core wires. Our professional team conducts thorough tests to measure performance and rank products based on established benchmarks. Every review is backed by data and factual evidence, ensuring you get an accurate picture of each product’s strengths and weaknesses. We assess crucial factors like material quality, tensile strength, and ease of use. Our comparative evaluations will help you understand what sets the best flux-core wires apart from their competitors, making your decision-making process more straightforward. Trust us as we guide you through the world of flux-core wires, providing you with the results of our research in an easily understandable format.

The Best Flux-Core Wires of 2024

There are multitudes of flux-core wires available on the market. Choosing the best one was a challenge.

Lincoln Electric ED031448 Flux-Core Welding Wire

Best All-Around Flux Core Wire

For all-around performance, this Lincoln Electric flux-core wire is pretty hard to beat. It gets a high rating on a well-known online site too. So, what is so great about it?

It is made from strong mild steel, and it is ideal for MIG welders. It comes in reels of 1.15 pounds, and the diameter is 0.030 inches, so it is better suited to welding machines with lower amperage.

This is also an ideal candidate for on-the-spot welding tasks involving dirty or rusted metal, thanks to the freezing characteristics of the wire.

Pros

- Ideal for MIG and stick welding.

- Great brand name.

- 0.030-inch gauge.

- Ideal for rusted and dirty metal.

Cons

- Small reels.

- Better with low amperage machines.

Product Specs

| Weight (pounds) | 1.15 |

| Dimensions (inches) | 10.5 x 5.75 x 4.25 |

| Tensile strength | 70,000 PSI |

| Diameter (inches) | 0.030 |

| Material | Mild steel |

| Price | $ |

Our Ratings

User Experience

Forney 42300 Flux-Core MIG Wire

Best Flux Core MIG Wire

This Forney flux-core wire is suitable for all welding positions, and like the Lincoln Electric wire, it is ideal for using on rusted, dirty and painted metal surfaces. This makes it the perfect wire to have handy for on-the-spot repairs like farm machinery and construction sites.

It is a 0.030-inch diameter wire, suitable for single-pass applications with a high travel speed. It comes in 2-pound spools, has a tensile strength of 79,000 PSI, and it produces minimal spatters.

This wire is made of mild steel and is suitable for MIG welding. You can add argon gas to reduce the spatters further, but it works just as well without shielding gas.

Pros

- Low spatter.

- High tensile strength.

- Suitable for MIG welding.

- 2-pound spools.

Cons

- Suited to low amperage machines.

Product Specs

| Weight (pounds) | 2 |

| Dimensions (inches) | 1 x 4 x 4 |

| Tensile strength | 79,000 PSI |

| Diameter (inches) | 0.030 |

| Material | Mild steel |

| Price | $$ |

Our Ratings

Personal Perspective

YESWELDER 0.030-Inch Flux-Core Welding Wire

Best 0.030-Inch Flux Core Wire

This mild steel wire gives good coverage, has low spatter and produces slag that is easy to remove. It also has low porosity and provides a good bead appearance. Unlike other flux-core wires, this is suitable for single and multi-pass welding. It also operates in any welding position.

You can use this wire on multiple applications, including butt, lap and fillet welds, and it is equally at home welding clean and dirty metal, making it ideal for on the spot repairs.

This wire comes in 2-pound reels and has a tensile strength of 79,000 PSI. Plus, it comes in a vacuum-sealed pack, so that it can be stored for a long time without the risk of the wire going bad through moisture penetration.

Pros

- High tensile strength.

- 2-pound reels.

- Vacuum-sealed packs.

- Useful for multiple applications.

Cons

- Made in China.

Product Specs

| Weight (pounds) | 2 |

| Dimensions (inches) | 4.21 x 4.13 x 2.12 |

| Tensile strength | 79,000 PSI |

| Diameter (inches) | 0.030 |

| Material | Mild steel |

| Price | $$ |

Our Ratings

Community Feedback

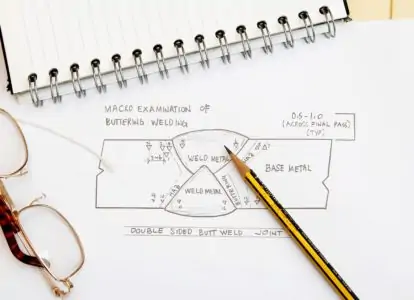

INETUB BA71TGS 0.030-Inch Flux-Core Wire

Best Gasless Flux Core Wire

This INETUB flux-core wire is Italian and produced to the highest standards. It comes as a 2-pound spool, has a diameter of 0.035 inches, and has full slag coverage. It is also a low spatter wire with easy slag removal when cooled.

It is also porosity-free and gives a good bead appearance. This wire is suitable for all welding positions, as well as single and multiple pass welding. It has a tensile strength of 82,700 PSI, making it one of the best in the business. This flux-core differs from the others featured because it is a carbon steel wire rather than mild steel.

Pros

- Carbon steel.

- High manufacturing standards.

- Non-porous.

- 0.035-inch diameter.

- Single or multi-pass.

Cons

- Quality control issues.

Product Specs

| Weight (pounds) | 2 |

| Dimensions (inches) | 3.94 x 1.85 x 3.94 |

| Tensile strength | 82,700 PSI |

| Diameter (inches) | 0.030 |

| Material | Carbon steel |

| Price | $$$ |

Our Ratings

First-Hand Impression

WeldingCity E71T-GS Flux-Core 0.035-Inch Welding Wire

Best 0.035-Inch Flux Core Welding Wire

If you like buying your flux-core wire in bulk, this Welding City 10-pound spool is the ideal purchase. And it’s an all American company. The welding wire comes wrapped in a vacuum-sealed pack to keep the flux-core from going bad and to prevent moisture from penetrating.

This is the first 0.035-inch diameter wire to feature, so it is suited to a welder with higher amperage. It also means you get a deeper penetration thanks to how the wire melts and creates a larger weld pool.

Like the others, it is mild steel and has a tensile strength of 70,000 PSI. Plus, this wire works on single pass welds rather than multiple passes.

Pros

- 0.035-inch diameter.

- High tensile strength.

- 10-pound spool.

- Better penetration.

Cons

- Single-pass only.

Product Specs

| Weight (pounds) | 10 |

| Dimensions (inches) | 8.4 x 8.4 x 2.5 |

| Tensile strength | 70,000 PSI |

| Diameter (inches) | 0.035 |

| Material | Carbon steel |

| Price | $$$$ |

Our Ratings

User Experience

Blue Demon E71TGS 0.030 Gasless Flux-Core Wire

Best Flux Core Wire for Rusty Metal

This Blue Demon wire is great if you want to weld galvanized roofing sheets and car body parts. It is an all-position, single pass flux-core wire, even vertically and overhead.

Typically, this wire is used to make lap and butt joints on sheet material, but it is also ideal for welding dirty and painted metal. This makes it a great accessory to have around the ranch or farm for on-the-spot welding repairs.

It has a tensile strength of 70,000 PSI, and it operates on a DCEN with a straight polarity.

Pros

- High tensile strength.

- Ideal for dirty and painted material.

- All-position wire.

- Welds carbon steel.

Cons

- Single-pass only.

Product Specs

| Weight (pounds) | 2.13 |

| Dimensions (inches) | 4 x 4 x 2 |

| Tensile strength | 70,000 PSI |

| Diameter (inches) | 0.030 |

| Material | Not stated |

| Price | $$ |

Our Ratings

Personal Perspective

| Product | Best | Weight | Dimensions | Tensile strength | Diameter | Material |

|---|---|---|---|---|---|---|

| Lincoln Electric Flux-Core Wire | All-Around | 1 lb | 10.5 x 5.75 x 4.25″ | 70,000 PSI | 0.030″ | Mild steel |

| Forney Flux-Core MIG Wire | MIG Wire | 2 lbs | 1 x 4 x 4″ | 79,000 PSI | 0.030″ | Mild steel |

| YESWELDER Flux-Core Welding Wire | 0.030-Inch | 2 lbs | 4.21 x 4.13 x 2.12″ | 79,000 PSI | 0.030″ | Mild steel |

| INETUB BA71TGS Flux-Core Wire | Gasless | 2 lbs | 3.94 x 1.85 x 3.94″ | 82,700 PSI | 0.030″ | Carbon steel |

| WeldingCity E71T-GS Flux-Core Welding Wire | 0.035-Inch | 10 lbs | 8.4 x 8.4 x 2.5″ | 70,000 PSI | 0.035″ | Carbon steel |

| Blue Demon Gasless Flux-Core Wire | Rusty Metal | 2 lbs | 4 x 4 x 2″ | 70,000 PSI | 0.030″ | Not stated |

What Is a Flux-Core Wire Used For?

A flux-core wire adds molten metal to the weld pool to increase the weld joint’s tensile strength, no matter what the conditions. It enables you to weld outdoors in challenging circumstances without the use of shielding gas.

It also means that repairs to machinery can happen on the spot because flux-core wire works just as well in clean conditions as it does on dirty or rusted metal. Plus, if you are welding vertically or overhead, flux-core wire solidifies faster, making it possible to achieve these welding angles without losing the weld pool.

How To Choose the Best Flux-Core Wire

Several factors make up the ideal flux-core wire. We run through some key aspects to consider.

Flux Core Wire FAQs

Down To The Wire

Flux-core wire frees you to weld in all conditions without worrying about shielding gas. It means you can make on-the-spot repairs to keep your farm machinery going or fix something to avoid delays.

It also means you can mend dirty and painted metal, increasing your versatility and welding range.