Stick welding is a popular method of welding. It is cheap and accessible to most welders and is effective in most outdoor weather conditions. This is because it requires no shielding gas.

We show you how to stick weld with all the hints and tips you need.

Key Takeaways

- Stick welding is a versatile and cost-effective method, ideal for outdoor conditions and various metals.

- Practice is key to mastering stick welding, focusing on weld joint preparation, electrode selection, and proper technique.

- Understanding and adjusting the five operating variables (CLAMS) is crucial for achieving better welding results.

- Always prioritize safety when stick welding, using proper personal protective equipment and following safety guidelines.

How Does Stick Welding Work?

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a welding method that uses an electrode and an electrical current at the weld pool to join different metals. It gets its name from the solid metal rod or stick that makes up the electrode. The stick is coated with metal compounds and binding agents to get it to stick. This is known as flux-coating.

Electrodes come in 3 categories, and they obtain their name thanks to the material they are coated in. The different coating types help optimize performance in applications by how they react to slag freeze, penetration and deposition rate. The coating also enhances the quality and stability of the arc.

What Can I Weld With a Stick Welder?

It can weld cast iron, mild steel, stainless steel, aluminum, magnesium, and other non-ferrous metals. It can also weld nickel and copper alloys. Stick welding is better suited to thicker materials and even works on painted or rusted surfaces. It is the ideal method of welding for performing on-site repairs to machinery and infrastructure.

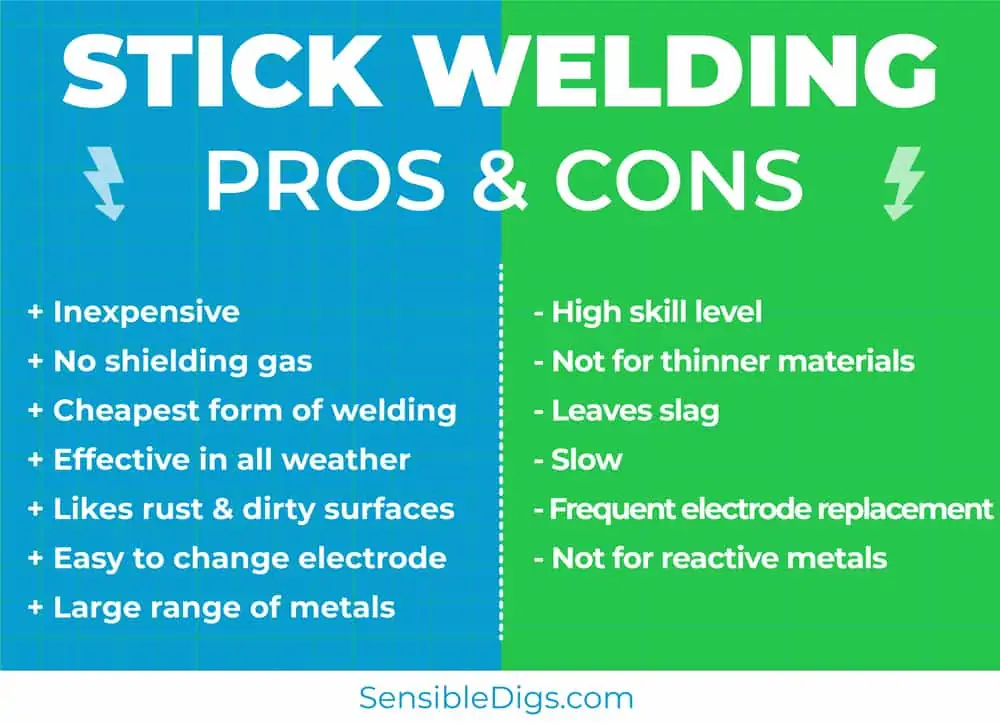

Advantages of Stick Welding

- Inexpensive equipment and set-up.

- Doesn’t require shielding gas.

- Cheapest form of welding.

- Effective in all weather conditions.

- Likes rust and dirty surfaces.

- Easy to change the electrode.

- Works on a large range of metals.

Disadvantages of Stick Welding

- Requires a high level of skill.

- Not great with thinner materials.

- Leaves slag to chip off.

- Stick welding is slow.

- Electrodes need replacing frequently.

- Not suitable for reactive metals like titanium.

What You Need

There are a few basic elements you are going to need to stick weld successfully.

- Power supply.

- Stick welding machine.

- Electrodes and spares.

- Rod holder.

- Ground clamp.

- Safety glasses.

- Face shield.

- Welding gloves.

- Welding jacket or protective sleeves.

- Face mask and an extractor if indoors.

- Wire brush.

- Small hammer to chip off slag.

How To Stick Weld

Stick welding may be popular, but that doesn’t mean it’s easy to master. It requires dedication, skill, and patience to get it right.

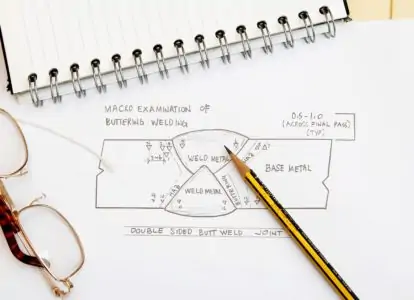

Weld Joint Preparation

The weld area should be as clean as you can get it. Remove mill scale, paint, oil, rust and water, as a minimum standard. Stick welding is effective at welding joints that are rusty and painted, but if you want the best results, always have a clean weld area.

You can do this with a grinder. Grind the metal surface so that the metal underneath is shiny. If you are unsure if you have achieved the right level of cleanliness, grind back by 1-inch.

Electrode Selection

Back in the day, all electrodes were stamped with an “E” for electrodes. These days, they get graded using numbers. The first two digits refer to the strength of the welding rod. A 6010 electrode shows that the joint’s tensile strength is 60,000 pounds per square inch of weld, hence the 6 and the 0.

Steel has a tensile strength of around 36,000 pounds per square inch, meaning that the electrode is typically twice the strength of the steel it is welding.

The last two numbers refer to the quality of the flux shielding on the rod. Generally, the higher the number, the better quality of the shielding. It’s at this point we should also mention budget electrodes. They appear to be good value on the surface, but with lesser tensile strength and a lower quality flux coating.

The 3 most common types of electrodes are:

1. E6010

This is perfect for welding rusty and dirty metal. It has a deep penetration grade and welds well in all positions and settings.

2. E6013

This is a great all-rounder, excellent for welding cleaner and smoother joints. It has a superior penetration level, but not quite the same as the E6010.

3. E7018

If you want a neat and clean weld, this is your electrode of choice. You need to ensure the surface is free of blemishes and completely clean. It is the industry standard.

Stick Welder Setup

1. Set the Polarity

Choosing the right electrode is only half the battle; getting the welder set up correctly is the other half.

Set the polarity according to the manufacturer’s guidelines. When done, set the amperage. Now fine-tune the welder to cater to the metal you are welding. This is important because different metals require different settings.

You can stick weld using AC and DC, although most industrial and commercial applications use DC. It’s better for welding steel, creates a more stable arc, is easier to get the arc started, and has less spatter.

2. Set the Arc Length

The arc length should be no longer than the diameter of the electrode. For example, a 6010 electrode should have a corresponding arc of around 0.125 inches.

3. Set the Sound

Most experienced welders can tell you whether a welder is set correctly by the sound it makes. The sound should be akin to eggs frying in a pan. If the rod glows red, you have the settings too high, and if the rod is too cold, it will stick.

Once you’ve tuned your ears to the correct sound, feel the rod’s vibration, as this will tell you a lot about your set-up.

Stick Welding Technique

Now that you have the welder set correctly, it’s time to focus on the actual welding technique. Before starting, learn to hold the stick the correct way, using two hands. Control is everything when it comes to welding, so get comfortable and brace yourself for every eventuality.

1. How To Strike an Arc

Starting an arc is not easy. As you learn the technique, you will likely chip the rod and damage it in small parts. This happens to the best welders out there.

If you are wearing the correct welding gloves, you could hold the rod like a pool stick and strike it. Once the arc strikes, place your hand with the other one on the welding handle. The other technique is to start the arc-like striking a match against the base metal. This is effective, but keeping the arc is more of a challenge.

2. Moving the Electrode

There are different welding techniques for different welds.

3. Whipping the Electrode

The backward and forward motion works well if you are trying to weld a dirty or rusted surface. It also works well on thinner metals and fillet welds (joining two metal pieces in an L-shape).

4. Circle Welding

This is an excellent technique for beginners. Move the electrode forward slightly with every new circle. It is slower than other methods, but it does help you control the speed of travel.

5. Weaving the Electrode

Moving the electrode from side to side is perfect for wider welds and is the method most experienced welders use. It adapts to smaller welds, but the weave size and thickness need to be adjusted.

Stick Welding Position

The electrode changes angle depending on the position of the weld.

1. Flat

Drag the rod at an angle of 10 to 30 degrees in the direction of travel. It might be easier to work from left to the right.

2. Horizontal

Position the rod upwards at an angle of 30 to 40 degrees. Now tilt the rod by 10 to 30 degrees as you drag it in the direction of travel.

3. Vertical

Angle the rod upwards between 30 and 40 degrees. There are two ways to travel, depending on the amount of flux on the electrode. E6010, E6011 and E6013 are better for vertical down, while E7018 electrodes prefer the other direction because slag gets caught in the weld.

4. Overhead

Use the same technique as working on the flat, except you point the rod upwards. The direction of travel should also be the same, from left to right.

5 Important Operating Variables (CLAMS) for Better Results

Get the 5 operating variables right, and you will be welding like a pro in no time. But what are they?

Current

This is set by the welding machine at the power source control. You can choose between AC and DC, although most welding tasks call for DC. It’s better for creating a stable arc and provides less spatter.

Length of Arc

The arc should be no longer than the diameter of the electrode. You should aim for an arc length of between 0.063 inches to 0.094 inches. The voltage varies depending on the size of the arc. Push it close to the weld pool, and it cools, while a longer arc creates more heat.

Angle of Travel

Depending on your position, place the electrode at the correct angle. On the flat, it should be between 10 and 30 degrees, horizontal between 30 and 40 degrees, and vertical should be 30 to 40 degrees. Overhead is the same as working on the flat.

Manipulation of Electrode

Experienced operators have many ways to manipulate the electrode, but the methods vary depending on the electrode, amperage, position, joint configuration and weld type. First, start by practicing the drag technique on a flat, straight piece of metal, and step it up a little by adding a circular motion.

Speed of Travel

Travel speed dictates the puddle width. Adjust the speed to create puddles that are no more than 1.5 to 2 times the diameter of the electrode.

Stick Welding Safety

Unlike other professions, when it comes to welding, you cannot take chances with safety. One mistake could be disastrous, leaving you seriously hurt or even maimed for life. Follow a strict safety code every time you pick up a stick to weld.

Here’s a list of the PPE that you will need:

- Goggles.

- Face shield.

- Leather gloves.

- Welding sleeves or a protective leather jacket.

- Welding respirator or extractor if indoors.

- Leather work boots or fire-proof shoes.

- Long-sleeved, non-flammable shirt.

- Non-flammable trousers.

- Fire extinguisher.

When welding, you should never act recklessly. A moment’s lapse in concentration can be treacherous. You will struggle to find a welder who hasn’t suffered from flash burns, or worse, eye flash from the arc.

It feels like you have grit in your eye, and it can take a few hours to manifest, so you generally don’t know you have it until a few hours after you have stopped welding.

Common Mistakes and Troubleshooting

As with all methods of welding, some mistakes happen that affect the overall result. Here are some common ones and how to correct them.

1. Spatter

Spatter is a common issue with stick welding. They are droplets of molten metal that deposit near the welding arc. To reduce the instances of spatter, reduce the current and the length of the welding arc. The longer the arc, the higher the heat produced. You could also check you are using the correct polarity, as this increases the chances of spatter.

2. Porosity

Porosity starts with contamination of the weld pool. Moisture is the biggest culprit, as is rust, dirt, grease and paint. To resolve this, always ensure that the weld area is spotlessly clean. Stick welding is great for welding in all types of conditions, but the cleaner the weld area, the stronger the weld.

Contamination can seriously compromise the quality of your work.

3. Undercut

Undercut occurs when the voltage is too high, or you have the wrong electrode for the thickness of the metal. It also happens if the welding speed is too rapid. If the electrode is too big, the amount of molten metal accumulates, causing undercut.

The way to avoid this is to lower the voltage, check you are using the correct electrode, and employ a weaving technique when laying down the weld.

4. Deformation

Deformation is common and occurs as the metal contracts as it cools. It happens when the metal hardens too rapidly, poor plate fit-ups and insufficient clamping, and too many thin beads. To avoid this happening, try welding from the center out, or weld both sides of the joint.

Also, try a larger electrode and reposition the weld line, or lay fewer beads.

5. Cracks

Cracks can be dangerous, no matter how small they are. In construction, they are a sign of a defect and weaken any structure. You cannot simply refill the gaps with new material. The cracks need to be ground out completely and rewelded.

Check you are operating the stick using the correct heat setting. Also, reheat both sides of the joint before welding so that they are the same temperature. Spend time deburring and cleaning the edges of the joint, so you get the neatest possible fusion.

Stick Welding FAQs

Stick To The Facts

Stick welding is popular, but that doesn’t make it easy to master. It is notoriously challenging to get right, but you will be able to weld outdoors in all weather conditions when you do. Stick is the cheapest to set-up, the least expensive to operate, and the most cost-effective for beginners.

What are you waiting for? Get stick welding, and never look back.