“What size air compressor do I need?” is a common question. Knowing the airflow limits of your power tool and the PSI is crucial, especially when matching it to your compressor for compatibility.

We run through air compressor sizes and give you the lowdown on different models to help you make an informed choice. So, let’s get started.

Key Takeaways

- Understand CFM and PSI: CFM (Cubic Feet Per Minute) refers to airflow, while PSI (Pounds Per Square Inch) refers to air pressure. Know the CFM and PSI requirements of your air tools to choose the right air compressor.

- Consider project size: The size of your project will determine the ideal air compressor size. Larger projects require compressors with larger tank capacity and higher PSI and CFM ratings.

- Assess tank size and style: Different compressor styles have varying tank capacities. Choose the right style (pancake, pontoon, twin stack, wheelbarrow, or vertical) based on your specific needs and available space.

- Power source and noise level: Decide between gas-powered or electric air compressors based on portability and power requirements. Consider the noise level of the compressor and take steps to reduce it if necessary.

Air Compressor Size Based on Air Requirements

Sizing an air compressor is based on airflow, known as Cubic Feet Per Minute (CFM), and Pounds Per Square Inch or PSI. Pneumatic tools require a supply of compressed air, and the efficiency of your compressor is measured in these two elements rather than horsepower.

CFM Requirements (Airflow)

Airflow is crucial if you want to get the most from your pneumatic tools. CFM is a standardized system of grading airflow. Typically, most air tools require 70 to 90 PSI, and the CFM changes depending on the PSI setting, so airflow is most commonly rated on performance at 90 PSI. The higher the number, the better the airflow.

Knowing the correct CFM ratings for your pneumatic tool is vital. So, how do you find out?

The CFM requirement of your power tool is listed in the handbook or the owner’s manual. To determine the correct size of the air compressor, multiply the CFM by 1.5. Here’s an example: If you want to run a spray gun with a CFM of 6.5, multiply 6.5 x 1.5, and you will need an air compressor with a minimum CFM of 9.75.

Most air tools are rated up to 5 CFM, although some require less airflow than others, while other, heavy-duty tools use more.

PSI Requirement (Air Pressure)

PSI and CFM go hand in hand. All air compressors have a listed PSI rating, and it is simple to find out. Larger compressors have a significantly higher PSI compared to smaller, compact models.

As a rule of thumb, most compressors are graded at 135 PSI, so as long as you aim for this pressure rating, you should be fine. Air tools generally require 70 to 90 PSI, and you will need a 20 percent gap between the device and the compressor PSI. Here’s an example:

An air hammer with a PSI rating of 70 will only work if the compressor has a PSI of 90 or above. The 20 percent difference ensures enough pressure to get the best from the tool so that there is a minimal drop in pressure.

If you try and run a pneumatic tool without the correct PSI gap, the tool will struggle.

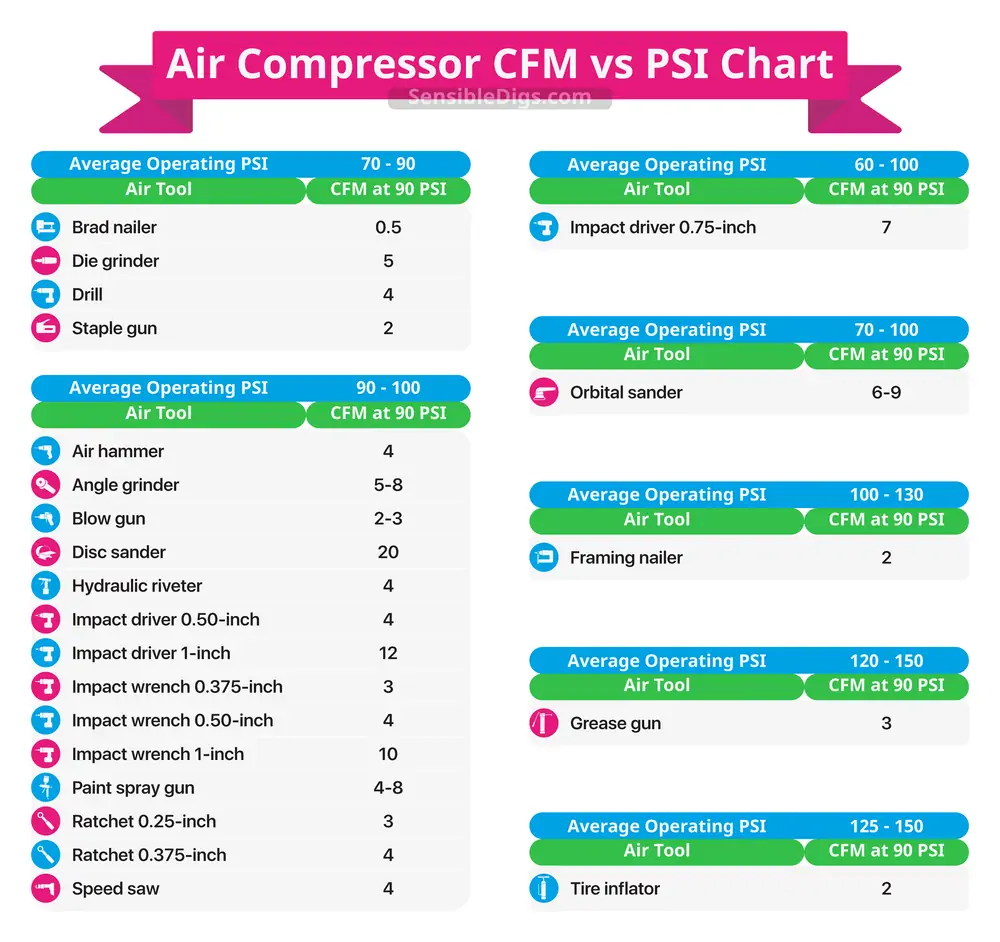

Air Compressor Size Chart for Common Tools

As we’ve said, the most common air tools have a 70 to 90 PSI rating and a CFM value up to 5, but what are the specifics of each. Here’s a handy chart.

When selecting the compressor, remember that most air tools have a duty cycle of about 25 percent, which means that you get 15 seconds runtime every 60 seconds. For continuous cycle tools like grinders, this rule does not apply.

| Air Tool | CFM at 90 PSI | Average Operating PSI |

| Air hammer | 4 | 90-100 |

| Angle grinder | 5-8 | 90-100 |

| Blow gun | 2-3 | 90-100 |

| Brad nailer | 0.5 | 70-90 |

| Die grinder | 5 | 70-90 |

| Disc sander | 20 | 90-100 |

| Drill | 4 | 70-90 |

| Framing nailer | 2 | 100-130 |

| Grease gun | 3 | 120-150 |

| Hydraulic riveter | 4 | 90-100 |

| Impact driver 0.50-inch | 4 | 90-100 |

| Impact driver 0.75-inch | 7 | 60-100 |

| Impact driver 1-inch | 12 | 90-100 |

| Impact wrench 0.375-inch | 3 | 90-100 |

| Impact wrench 0.50-inch | 4 | 90-100 |

| Impact wrench 1-inch | 10 | 90-100 |

| Orbital sander | 6-9 | 70-100 |

| Paint spray gun | 4-8 | 90-100 |

| Ratchet 0.25-inch | 3 | 90-100 |

| Ratchet 0.375-inch | 4 | 90-100 |

| Speed saw | 4 | 90-100 |

| Staple gun | 2 | 70-90 |

| Tire inflator | 2 | 125-150 |

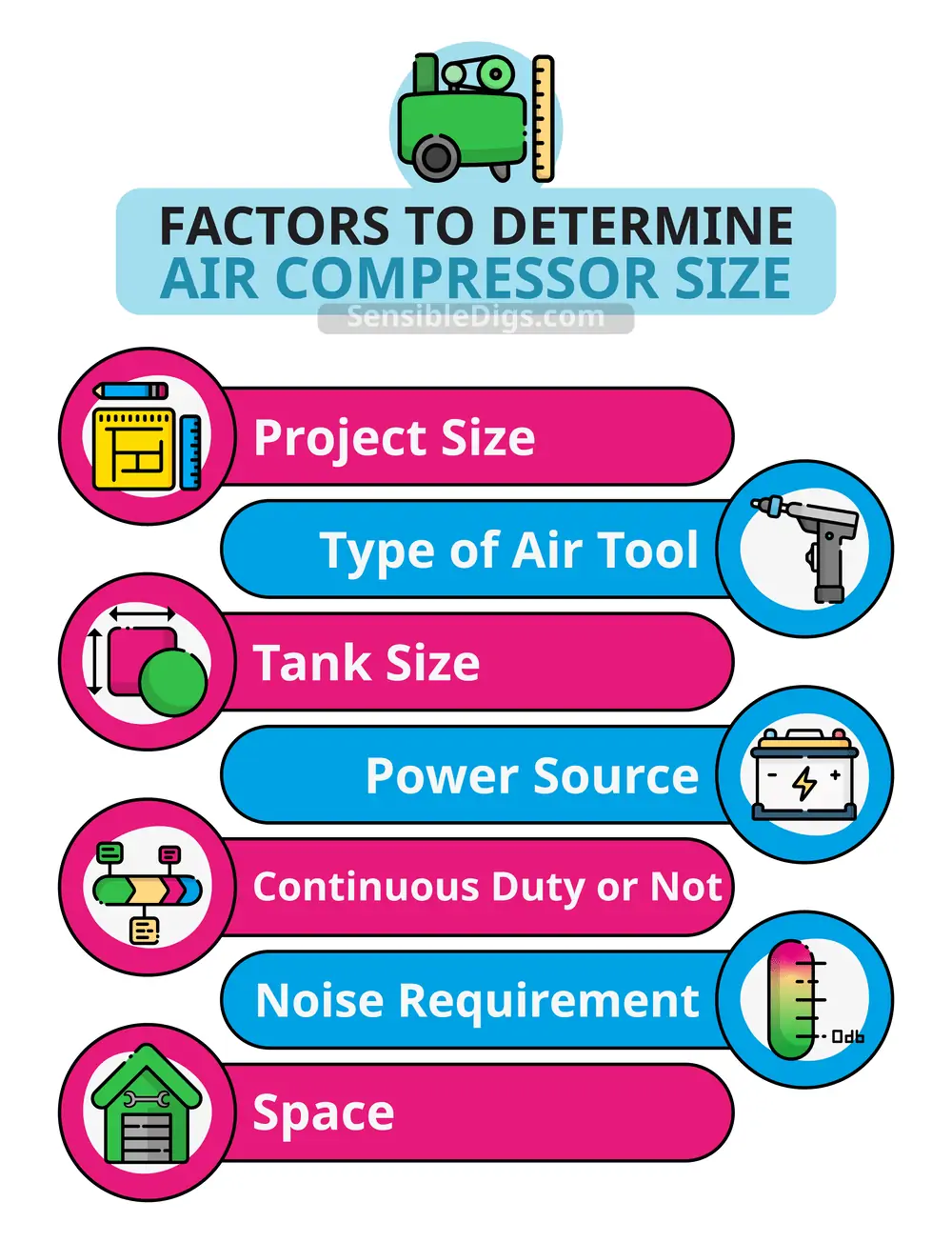

Factors To Determine Air Compressor Size

Working out which air compressor is right for the job and the tool you have takes many considerations. Here are the fundamentals you should consider.

Project Size

The size of the project is crucial when determining the size of the air compressor you need. You won’t make your life easier if you get a compact compressor with a small tank capacity when you are laying flooring using a nail gun. For sustained tasks, seek out a compressor with a large tank capacity and enough PSI and CFM to handle a heavy-duty air tool.

Type of Air Tool

As the chart above shows, not all air tools are equal in the CFM they require and the PSI. Choosing an underpowered compressor will lead to sluggish tools and a poor outcome. Make sure you understand the PSI ratings given to each device. You can find this in your user manual.

It’s also important to leave yourself some wiggle room when determining the compressor’s size because you may want to attach multiple tools or upgrade to a more powerful option. Plus, not every task is a gentle one. Some projects require brute force, and if you buy an air compressor that consistently underperforms, it could result in you purchasing a more powerful and more expensive compressor.

Tank Size

This determines how often you will need to recharge the tank and the size of tools and projects you can undertake. First, sustained tasks require a constant supply of compressed air. If the tank is too small, it will result in a loss of pressure as the cylinder empties and a dip in the tool’s performance.

If time is money, be prepared to take numerous breaks as you wait for the tank to fill.

Second, the tool’s CFM and PSI rating could affect the speed at which it consumes compressed air. Larger devices are hungrier and will deplete your tank supply faster. With this in mind, there are several styles of compressors with varying tank capacities.

1. Pancake

Pancake compressors are small and lightweight and are a particular favorite for home and hobby users. They typically have a capacity of between 3 to 6 gallons, so they are better suited to lighter duties.

2. Pontoon

These compressors are sometimes called horizontal because they have a tank that lays flat rather than vertical. They typically range in capacity from 1 gallon to 30 gallons. At the larger end of the scale, these compressors can be stationary models designed to sit in one place.

They have CFM ratings ranging from 5 to 15 or even higher, depending on the capacity. Also, the PSI varies from 135 to 200 in some models.

3. Twin Stack

Twin stack models have a distinct advantage over single-tank models in that you can always rely on a fresh supply of compressed air. As one tank empties, the other remains full, and as you empty the second tank, the first one refills. It also means you increase your tank capacity because you have two tanks.

They are lightweight and portable, but thanks to the twin tanks, their bulk is increased. You should expect a capacity of between 5 and 10 gallons and a PSI rating of 135 to 150. The CFM values vary between 2 and 5.

4. Wheelbarrow

They have large handles at one end and one pneumatic wheel at the other, hence the name. Imagine a twin-cylinder compressor with wheels. They are easier to maneuver, even when they have a capacity of 10 gallons, making them the ideal choice for professionals who are always on the move from job to job.

While they are portable, you wouldn’t class them as light. Some can weigh as much as 150 pounds! At the top end, the PSI and CFM values can reach 150 and 10, respectively, but for smaller models, this drops to 125 PSI and 5 CFM. Another interesting feature of wheelbarrow compressors is that, in the main, they are gas-powered, making them the ultimate go-anywhere air compressor.

5. Vertical

If you work in confined spaces, a vertical air compressor is a great choice. On the smaller models, ranging from 10 gallons to 30 gallons, they have wheels and a handle to help you get them into position, but the 60-gallon models and above are stationary compressors, designed to sit in one place.

Power Source

When choosing your next compressor, it is worth considering what type of power source you want. There are two options available to you.

1. Gas

Gas-powered compressors are go-anywhere models. They do not require an electrical supply, so they are the ideal candidates for building site work. They tend to be more powerful, producing the highest CFM and PSI values.

If you have a heavy-duty project and want the most power to your elbow, gas compressors deliver. They also have bigger horsepower. The downside is they are noisy, can weigh in excess of 300 pounds, depending on the model, and cost 3 or 4 times the price of their electrical cousins.

Gas-powered compressors have a very long usable life, with some lasting 20 years plus.

Pros

- More power.

- Go-anywhere tools.

- Robust.

- Longer runtime.

- Increased lifespan.

- Higher CFM and PSI values.

Cons

- Expensive.

- Heavy.

- Costly to run.

- Require increased maintenance.

- Better for professional use.

2. Electric

These are the most common models by far, favored by professionals and hobbyists alike. While they struggle to reach the giddy heights of performance that gas-powered models produce, they are still powerful compressors.

They range in sizes, style, and capacity, from hand-held tire compressors to 120-gallon stationary models that serve auto shops, factories, and workshops across the country.

The advantage is they are cheaper to buy and more commonly found, along with lower running costs because you don’t need gasoline. The downside is they need an electrical supply, and they are not as powerful as the gas models.

Pros

- Many makes and models.

- Cheaper than gas models.

- Portable.

- Require less maintenance.

- Powerful.

- Cheaper running costs.

Cons

- Not as powerful as gas models.

- Requires an electrical supply.

- Not a go-anywhere tool.

Continuous Duty or Not?

This, again, depends on the type of tools and projects you undertake. If you are using the compressor intermittently, a duty cycle of 50 percent is fine to get the task done. However, if you are a professional looking to complete significant projects in a timely manner, a continuous cycle is crucial to your reputation.

Some air tools have a limited duty cycle, so even though the compressor can accommodate a continuous cycle, it might be a moot point as the tool cannot. You also have to account for the increase in temperature and how well the motor copes without overheating.

Noise Requirement

Air compressors are noisy, full stop. However, that is not the whole story. Some air compressors are quieter than others, and some air compressors are better at dulling the sound they make.

The general rule of thumb is the larger the compressor, the noisier it becomes. Higher powered motors, air intakes, and increased vibrations add to the cacophony of noise. There are models, like the California Air Tools range, that run at a lower decibel level, but in truth, you will want ear defenders.

There are steps you can take to make your air compressor quieter.

- Regular maintenance.

- Changing air filters regularly.

- Building a soundproof box.

- Rubber matting.

- Soft pads for the feet.

- Locating the compressor away from a wall.

- Locating the air intake outside.

- Fitting a muffler.

It’s worth remembering that the Occupational Safety and Health Administration (OSHA) warns that prolonged exposure to volumes above 85 dB is harmful to your hearing. So, reducing the noise your compressor makes is crucial to protect your health.

Space

When selecting the desired air compressor, double-check the dimensions and visualize how it will look in your available space. Smaller air compressors are compact, so this is less of an issue, but 30, 60, and even 120-gallon air compressors are behemoths and can seriously shrink the available workspace in a room.

If space is a consideration. Think about a vertical compressor rather than a hot dog or wheelbarrow style. They take up less room and are easier to store away.

FAQs

Don’t Get Stressed About Compressed

Sizing your air compressor takes time, thought, and research. Get to know the tools you have and audit their PSI and CFM requirements to ensure they are all covered. Think about the tank capacity and the projects you are undertaking.

Also, where is the compressor going to sit? Once you have it straight in your mind, all you have to do is make the right choice. Good luck.