Air compressors are loud. That’s a fact. But you can either accept that your air compressor is noisy, or you can do something about it. With a few modifications, you can reduce your air compressor’s volume to make it more bearable to use.

We spare your hearing and show you how to quiet an air compressor.

Key Takeaways

- Install rubber feet or grommets to reduce vibrations and noise.

- Extend the air intake to decrease the loudness of the air compressor.

- Regularly change filters to maintain efficiency and reduce noise.

- Build a soundproof box to significantly lower the volume of your air compressor.

Why Are Air Compressors So Loud?

It seems that budget models and those with higher horsepower make the most noise. Unfortunately, because air compressors are designed for use in noisy environments, many manufacturers simply ignore this aspect in their production process.

So what contributes to all that racket?

Horsepower

The bigger the engine and the more power it has, the louder it becomes. Imagine a powerful sports car engine without the hood and the bodywork, and you get some idea why larger capacity air compressors get so loud.

According to the Occupational Safety and Health Administration, repeated exposure to volume levels above 85 dB can result in hearing loss (1). Taking noise reduction seriously is crucial if you want to preserve your hearing.

Friction

Friction could also be the cause of unnecessary noise. Metal striking metal makes a lot of sound. Make sure the air compressor is on stable ground and free from any obstructions. As the compressor fires up, if it is in contact with other objects, this could increase the loudness.

Age of the Compressor

Older compressors are noisier than their modern counterparts. They use outdated technology, employing little or no volume reducing techniques to quiet their air compressors.

Condition

Nothing ages a compressor more quickly than a lack of engine servicing. Just like a car, air compressor motors need some love and care. Oil changes should happen frequently, as well as replacing worn parts.

Failure to do this results in an inefficient compressor, which means it will be noisier.

What’s It Sitting On?

The type of flooring the compressor sits on could be the reason why the sound amplifies. Concrete is a pretty unforgiving surface when it comes to noise reduction. Also, suspended floors echo, enhancing the loudness of the compressor.

Build Quality

You’ll often hear it said that cheaper air compressors are noisier, and this is true. High-end models use better quality components and thicker and sturdier materials. This leads to vibration reduction, which lessens the volume.

Air Intake

Air intake is one of your biggest culprits when it comes to noise. Imagine the sound a vacuum cleaner makes, and you get some idea of how noisy the air intake can get. The air exhaust is another contributing factor to the volume. All that air by-product needs to exit the compressor somewhere.

How Loud Is an Air Compressor?

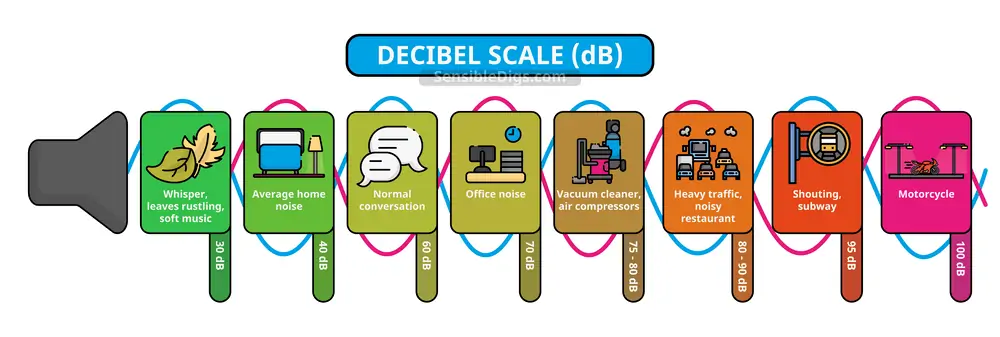

The best way to distinguish the loudness of air compressors is to judge them against other things. We need a recognizable equivalent sound so we can translate volume in a meaningful way.

All noise is measured in decibels, with everything graded according to the sound they make. You’ll often see comparisons with common activities like conversation and vacuum cleaner loudness to give us a better understanding of volume. Most air compressors operate between 60 and 90 dB. It does vary depending on the make, model, and capacity/size of the motor.

Larger air compressors are louder, while small models offer the best ear-comfort levels. Here are some typical values and how they compare, to give you an idea of how loud your air compressor is.

| Activity | Decibels |

| Whisper, leaves rustling, soft music | 30 |

| Average home noise | 40 |

| Normal conversation | 60 |

| Office noise | 70 |

| Vacuum cleaner, air compressors | 75 to 80 |

| Heavy traffic, noisy restaurant | 80 to 90 |

| Shouting, subway | 95 |

| Motorcycle | 100 |

It’s unlikely you will get an air compressor that goes above 100 dB.

Take Note

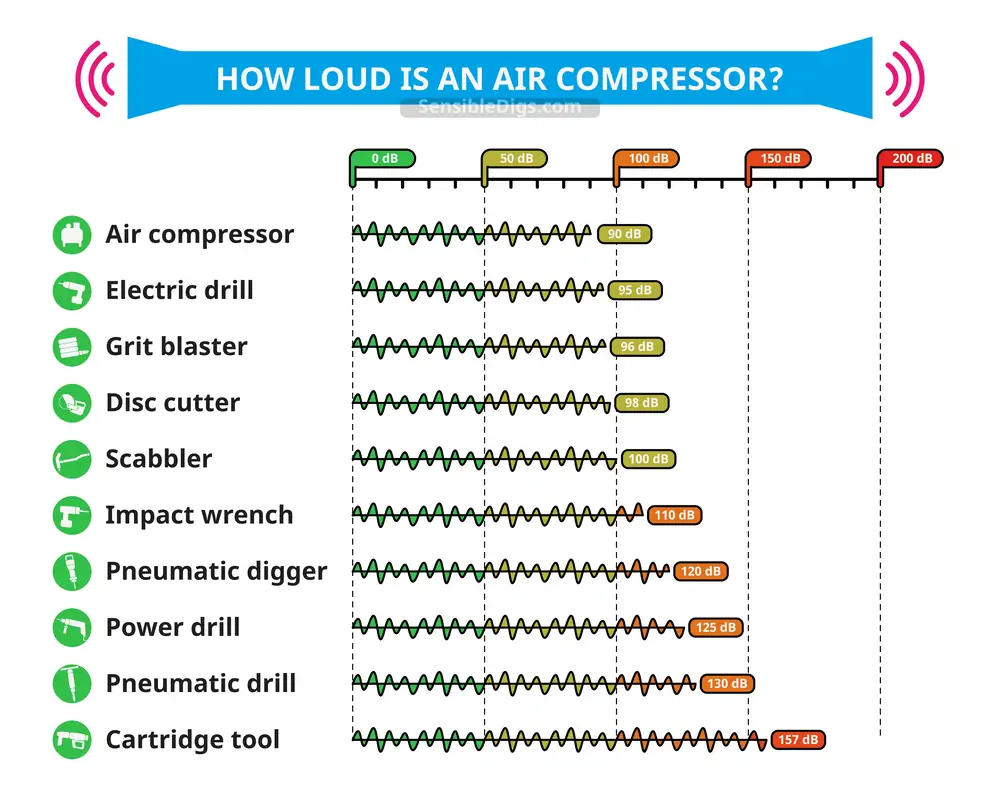

So, how do air compressors fare when compared to other power tools?

| Power Tool | Decibels |

| Electric drill | 95 |

| Grit blaster | 96 |

| Disc cutter | 98 |

| Scabbler | 100 |

| Impact wrench | 110 |

| Pneumatic digger | 120 |

| Power drill | 125 |

| Pneumatic drill | 130 |

| Cartridge tool | 157 |

It would appear that air compressors are at the lower end of the noise scale compared to typical everyday power tools.

What Is Considered a Quiet Air Compressor?

Quiet air compressors usually operate between 60 and 70 decibels. Some just peak above the 70 dB mark and can still be considered quiet, but in the main, below 70 is preferred. Some make and models make less noise than others, and size and capacity make a significant difference in the loudness performance.

By far, the quietest brand is the California Air Tool compressors. They produce devices that range in size and capacity, with the smaller ones, like the 1 horsepower 8-gallon air compressor running at a dB level of 60, and some of the larger models, like the 60-gallon capacity producing 75 dB.

When you compare the California Air Tools products with other similar models, you save almost 20 decibels on the noise levels.

OSHA Standards on Occupational Noise Exposure

The Occupational Safety and Health Administration has a minimum standard for working in a noisy environment. It is designed to protect the health and wellbeing of American employees from long-term health defects that could impact their quality of life.

It is estimated that 22 million workers are exposed to potentially harmful noise levels at work. If you have to raise your voice to be heard, there’s a strong chance that the noise level in your work environment is above 85 dB.

The OSHA requires that employers implement a hearing conservation program for workers exposed to volumes of 85 dB or above for 8 working hours a day, or an 8-hour time-weighted average (TWA). It prevents initial hearing loss and protects against further hearing loss for workers by equipping them with the knowledge and protective equipment to ensure a safe working environment.

How To Quiet an Air Compressor

If you suffer from noise pollution created by your extremely loud air compressor, don’t panic, there are some steps you can take to make life more bearable.

Install Rubber Grommets

As we’ve already said, vibration is one of the biggest offenders when it comes to noise levels, and the easiest way to eliminate excess sound is to dampen the vibrations. Rubber grommets have a fantastic sound-absorbing quality when placed correctly on your air compressor.

They are best located between your air compressor’s mount and the floor, making sure they don’t touch. As the compressor vibrates, the grommets absorb the impact and swallow up any excess sound.

You can also use rubber matting or EVA pads that sit under the air compressor’s feet.

Top Tip

Extend the Air Intake

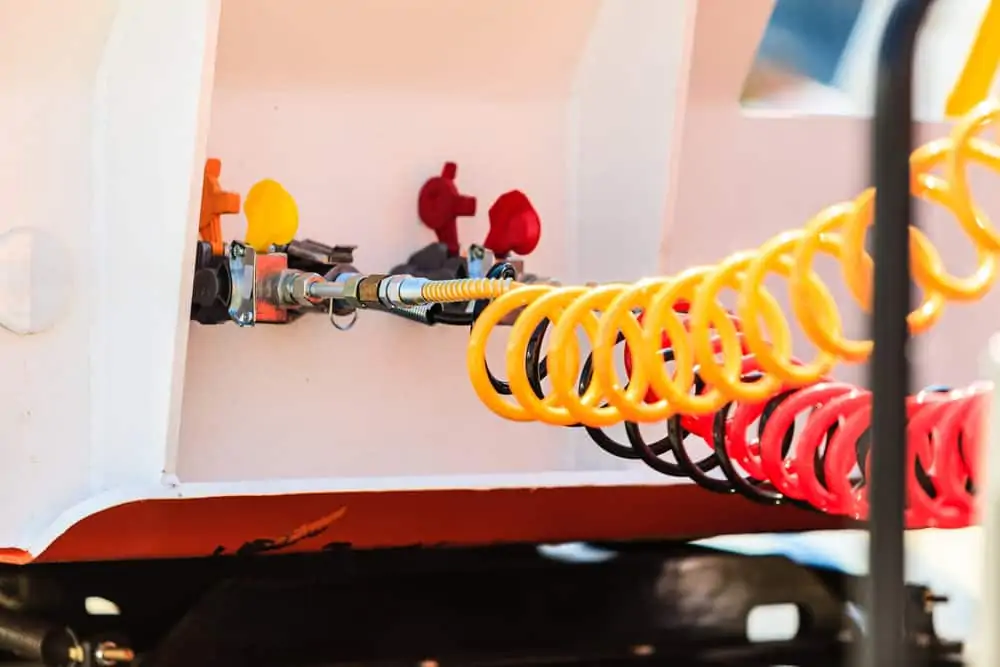

You could try extending the air intake component so that it reaches outside. The air intake is one of the noisiest elements on your air compressor, so locating the intake outside will significantly reduce the volume of your device.

You can convert the intake to reach outside using rubber hoses and a clamping bracket. Simply push the air hose over your compressor’s intake valve, holding it in place using the bracket. Then feed the other end of the hose outdoors, where noise levels are less of an issue.

If you open a door or a window to feed the hose, some residue of noise will leak back in, but if you drill a hole in the wall and feed the pipe through, it will dramatically cut the racket.

Install a Muffler

This is one of the easiest ways to reduce the volume of your air compressor. However, it could be expensive if you don’t have an old car muffler lying around. You will need two hoses and a muffler to achieve this.

Simply attach one end of the hose to your compressor’s air intake valve and the other to the muffler. Take the second hose and connect it to the other end of the muffler. It should reduce the noise by up to 4 decibels. To make further gains, you could extend the second hose outside.

Keep It Tight

Your air compressor is a solid unit, with every nut and bolt tightened to within an inch of their lives. However, vibrations can wreak havoc, causing tight bolts to loosen. As the unit becomes less reliable, it also creates more noise.

Before you use the compressor, it is worth giving it a once-over to check everything is as it should be. You should do this every couple of times you use the compressor, and it should be part of your maintenance program.

Clean the Air Filters

If you want to preserve the life of your compressor, keep the air filters clear. And that means a regular change. The air filters clean the air inside your compressor, so it stops any nasty contaminants from causing damage. However, dirty air filters also slow the airflow, reducing the compressor’s efficiency.

It has two significant effects. The first is your motor runs harder and longer to produce the air, and this increases the volume, and two, if the filters are rammed full of debris, the air cannot flow easily, making the whole process louder.

Quick Tip

Build a Soundproof Box

Many users recommend this as an effective option to reduce sound. It is a little more involved than other sound-reducing methods, but it does work wonders to reduce the volume.

To do this, you need some basic woodworking skills, some plywood sheets, a circular saw, a drill and screws, and soundproof foam. You should measure the air compressor’s dimensions before building the box and make sure you are generous with the sizing.

Remember that the compressor still needs air to ventilate inside the box, and you need to accommodate the extra layer of insulating foam. You should also drill air vents to allow the heat to escape. Make them as small as possible to cut down on noise leakage.

Plus, when you build your box, allow for the hoses and intakes. Once you have the basic shape, attach the foam to the walls and lid using an adhesive spray. While it does reduce the volume of your air compressor, it isn’t going to eliminate all the noise.

You can use a variety of materials other than wood. Concrete blocks with a sand-filled cavity make an excellent alternative while swapping expensive foam for soundproofing suspended ceiling tiles might be a cheaper alternative.

Situate the Compressor Correctly

Air compressors are louder when they are near walls. The sound they make bounces off the wall like a speaker, amplifying the volume. If you can, move the compressor away from any object so that it stands freely. If space is limited, try and deaden the amplification qualities of the wall.

You can use sound-reducing blankets or other material that dulls the noise, like foam or even carpet.

Wear Ear Defenders

This may seem like the obvious method, but you would be surprised by the number of people who ignore health and safety. Ear defenders dull the compressor’s sound, but the downside is they also block out other noises.

If you are in danger, someone calling to warn you will go unheard, which is why you should always practice competent safety precautions to avoid risk.

Silence Is Golden

Air compressors are noisy, that much we know, but there are many ways we can make our compressors a lot quieter to avoid trading your old one in for an improved model.

By spending a little money rather than a lot, most of the clever tricks and tips will save you hundreds of dollars and make your air compressor better, and that has to be good for your wallet and your ears.