Have you ever wondered what all the jargon means when you buy an air compressor? Just like all other performance tools, air compressors are rated on power, efficiency, and capacity, as well as a host of other things.

We talk you through air compressor ratings to get you up to speed.

Key Takeaways

- CFM (Cubic Feet Per Minute) measures the airflow of the compressor, with higher CFM meaning more power for heavy-duty tasks.

- PSI (Pounds Per Square Inch) is the measurement of pressure, and your compressor should have at least 20% more PSI than your air tools.

- HP (Horsepower) indicates the output rate of the motor or engine, with higher HP meaning a faster recharge of the air tank.

- Duty Cycle determines how long the compressor will run between rests, with a higher percentage allowing for longer operation times.

How Does an Air Compressor Work?

An air compressor uses either electricity, diesel, or gasoline to power a motor, which transfers power by compressing the air inside a storage tank. This is used to power air tools, as well as having other industrial and commercial uses.

Air gets drawn in through an intake as it passes through a chamber, where it is pressurized. It then gets forced along an outlet pipe into the holding tank, where it is stored until it is needed.

Air Compressor Ratings

So, how are air compressors rated? There are several standard terms you need to know when using or shopping for the best air compressor. Let’s take a look at some.

CFM (Cubic Feet Per Minute)

Cubic feet per minute or CFM is a measure of the airflow of the compressor. Each CFM unit is a rating of the compressor’s abilities to deliver enough compressed air to power your air tool. The higher the CFM, the more power the compressor has for tackling heavy-duty tasks.

CFM differs from SCFM (Standard Cubic Feet Per Minute) in that it measures the compressor’s ability in an environment that contains variables. Think of it a bit like a car manufacturer’s claims about average MPG (Miles Per Gallon) compared to actual “real life” MPG.

It’s the same for CFM and SCFM. CFM is the compressor’s value as it performs in everyday environments, coping with the demand, extreme temperatures, and the punishment of life in an industrial setting.

Thanks to these variables, CFM is measured at 90 PSI, which is the reason why CFM is always lower than SCFM.

SCFM (Standard Cubic Feet Per Minute)

SCFM is another popular method of rating your compressor’s capabilities. Unlike CFM, this calculation takes into account standardized conditions. Think of it like laboratory conditions, where the humidity, temperature, and pressure are known elements.

For this reason, SCFM readings are generally more generous than CFM ratings. If the mass flow rate passing through a surface in a given unit of time is graded under near perfect conditions, the values the compressor displays in normal working situations will likely differ.

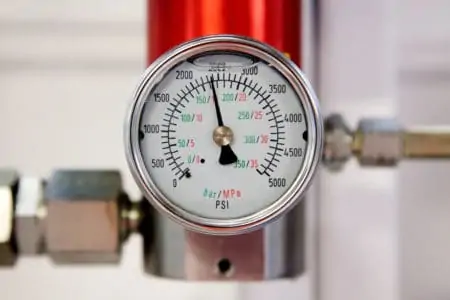

PSI (Pounds Per Square Inch)

Pound per square inch, or pound-force per square inch, to give it its more accurate name, is the measurement of a unit of pressure resulting from one pound-force when applied to an area of one square inch.

Understanding your compressor’s PSI is crucial because it means you can match its capabilities with your air tool. Air tools generally have a PSI rating of 70 to 90 PSI, with most compressors rated at a minimum of 135 PSI.

It is important to understand that your compressor should always have an excess of more than 20 percent PSI over your air tools to avoid a pressure drop and sluggish performance.

HP (Horsepower)

Horsepower is the output rate your engine or motor delivers. It is a literal comparison to how many horses it would take to produce the same performance as your compressor’s motor. HP is a term commonly used in the automotive industry to rate the potency of engines.

Engineer James Watts first coined the phrase in the late 18th century to compare the output of steam engines with the power of draft horses (1).

However, one horse does not equal one HP. A horse has over 14 horsepower and humans about 5. Watt designated his horsepower measurement as an equivalent to the amount of power a horse can sustain over an extended period.

Compressor engines are rated in HP as a way of telling you the amount of power they create. The higher the HP, the more capable your compressor is of producing a faster recharge of the air tank.

Duty Cycle

The duty cycle determines how long your compressor will run between rests. This is a vital consideration if you are looking for the best performance over extended periods. Most compressors have a duty cycle of 50 to 60 percent, but some larger, gas-powered models have 100 percent duty cycles.

To give you an idea of what a 60 percent duty cycle means, for every 10 minutes cycle time, you will get a running time of 6 minutes. This makes the duty cycle 60 percent.

To put it another way, if you have a duty cycle of 50 percent, for every minute of operation, you will get 30 seconds of runtime.

For home and hobbyists, the duty cycle is a minor consideration because most of the time, the compressor gets used infrequently. However, for professionals, where time pressures exist, it is crucial you choose the best duty cycle machine to get the job done faster. For every minute the compressor is silent, you risk losing income.

Gallons

Gallons refers to the tank size of your air compressor. Like cars, it is a unit of measurement that determines how much capacity the tank has. When you are sizing an air compressor it is vital because more gallons means your tank will hold more compressed air.

It increases your capabilities and the length and size of the projects you can undertake. It also indicates how often the compressor will need to recharge the tank during use.

FAQs

Rate My Compressor

While it all sounds like jargon and industry speak, knowing how to rate your new air compressor is crucial to getting the best tool for the job. CFM, PSI, HP, and the rest all have important messages to tell you.

If you ignore your air compressor’s vital statistics, you risk disappointment and possible increased costs to rectify your mistakes.