A drill is one of the foundations of a complete tool kit, whether you are a professional builder or simply performing maintenance on your home. Drill bits give a drill its versatility, allowing you to complete various tasks with minimal effort.

There are numerous drill bit types, each designed for different tasks and materials. This is great if you know what you’re doing, but it also means you might be confused by the various unusual bits that are in your toolbox.

In this guide, we will look at 20 of the most common types of drill bits and some of the tasks they can be used for. This should help you find the right bit for any job you need to tackle.

Key Takeaways

- High-Speed Steel (HSS) Bits: Great for drilling through steel, wood, and plastic.

- Brad Point (Wood) Bits: Ideal for precision work and drilling through wood and plastic.

- Masonry Bits: Designed for drilling into concrete, stone, and brick.

- Multi-Purpose Bits: Versatile bits that can drill through various materials like metal, wood, plastic, ceramic tiles, and masonry.

20 Types of Drill Bits Explained

1. High-Speed Steel (HSS) Bits

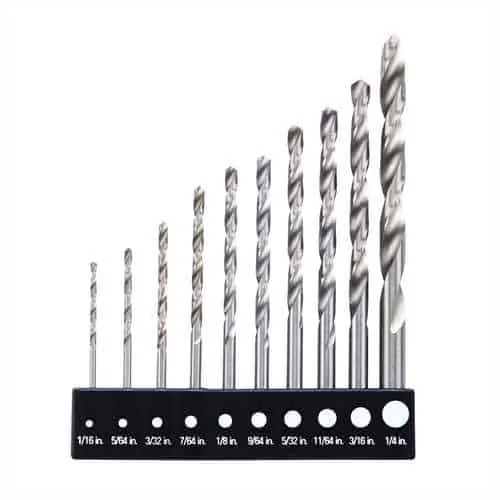

High-speed steel drill bits, often referred to as HSS bits, excel at drilling through steel. These drill bits take their strength from a mixture of vanadium and tungsten. They typically have a grade of 60 or above on the Rockwell hardness scale.

HSS drill bits are commonly referred to as twist bits due to their cylindrical shank and they are the go-to drill bit for general use. They are available in sizes ranging from 0.8 mm to 12 mm, and they are also suitable for drilling through wood and plastic.

Pros

- Can drill through steel

- Robust

- Very versatile

- Suitable for most common materials

Cons

- Can clog easily

- Smaller bits are brittle

- Sharpening damages the titanium

Product Specs

| Type | Twist Drill |

| Use | Wood, Metal, Plastic, Composites |

| Compatibility | Electric Drill, Power Drill, Hand Drill |

| Sharpening | Drill Sharpener, Grinder, Oilstone |

2. Brad Point (Wood) Bits

The brad point drill bit, also known as a spur point bit, has the same shape as a twist bit, but with a W-shaped tip. This allows the outer points to start cutting a hole before the center point makes contact with the material. Sizes range from 3 mm to 10 mm.

This means less resistance when drilling and a cleaner hole. Brad point bits are ideal for drilling wood and plastic, as well as tackling specific jobs such as doweling. These drill bits often have a depth stop that allows you to drill to a specific depth, which is ideal for precision work.

Pros

- Less resistance

- Excellent for precision work

- Depth stop

- Neat finish

- Ideal for wood

Cons

- Difficult to sharpen

- Unsuitable for drilling hard materials

Product Specs

| Type | Twist Drill |

| Use | Wood, Plastic |

| Compatibility | Electric Drill, Power Drill, Hand Drill |

| Sharpening | Grinder, Diamond File |

3. Masonry Bits

Masonry drill bits are intended for drilling into concrete, stone, and brick when the drill is set to hammer mode. They have a tungsten carbide tip for increased durability and a cylindrical or hexagonal shank to prevent them from slipping in the chuck when drilling tough material.

The maximum reach of a masonry drill bit is 400 mm, and they range in size from 4 to 16 mm.

Masonry bits are placed under a great deal of stress, which causes them to heat rapidly. If they get too hot, the tungsten coating can melt, and the drill bit can overheat. You should keep some cold water nearby to dip the bit into, and remove any debris from the bit as you work.

Pros

- Can drill through stone, brick, and concrete

- Robust

- Easy to sharpen

- Suitable for hammer settings

Cons

- Limited uses

- Overheat quickly

- Dull quickly

Product Specs

| Type | Twist Drill, Specialist |

| Use | Masonry, Concrete, Stone |

| Compatibility | Electric Drill, Power Drill, Hand Drill, Hammer Drill |

| Sharpening | Drill Sharpener, Grinder |

4. Multi-Purpose Bits

Multi-purpose drill bits are versatile bits that can be used for various tasks. They are suitable for hammer or rotary modes and have a diamond-ground tungsten tip. This allows them to drill through metal, wood, plastic, ceramic tiles, and masonry.

When drilling masonry, you should use the rotary mode because the hammer setting may damage the coated tip. To cope with the demands of prolonged masonry drilling, you should use a specialist masonry bit rather than a multi-purpose one.

Pros

- Multi-purpose

- Suitable for most materials

- Diamond-ground tip

Cons

- Unsuitable for heavy-duty masonry work

- Dulls quickly with constant hammer use

Product Specs

| Type | Twist Drill |

| Use | Wood, Plastic, Ceramics, Light Masonry |

| Compatibility | Hand Drill, Power Drill, Electric Drill |

| Sharpening | Drill Sharpener, Grinder, Diamond File |

5. Titanium Nitride HSS Bits

These bits are similar to standard HSS bits but with a titanium coating. The coating reduces overheating during use, giving these bits a lifespan of up to six times longer than similar uncoated drill bits. Like other high-speed steel drill bits, these bits can drill through wood, metal, and plastics.

This drill bit requires less maintenance than standard bits and is a great all-rounder.

Pros

- Reduces overheating

- Long-lasting

- Robust

- Great for drilling metal, wood, and plastic

- Requires less maintenance than uncoated bits

Cons

- Loses titanium coating when sharpened

- More expensive

Product Specs

| Type | Twist Drill |

| Use | Wood, Metal, Plastic |

| Compatibility | Hand Drill, Power Drill, Electric Drill |

| Sharpening | Grinder, Oilstone |

6. Cobalt HSS Bits

Cobalt HSS bits are made from precision-ground, alloyed high-speed steel and solid cobalt. They are incredibly hard-wearing and resistant to high temperatures and abrasion.

Cobalt drill bits can tackle steel, cast steel, stainless steel, cast iron, bronze, and other high-tensile steel. This sets them apart from the majority of drill bits and makes them among the toughest types you will find.

Pros

- Hard wearing

- Resistant to extreme temperatures

- Resistant to abrasion

- Drills high-tensile steel

Cons

- Unsuitable for drilling wood

Product Specs

| Type | Twist Drill, Specialty |

| Use | Metal |

| Compatibility | Hand Drill, Power Drill, Electric Drill |

| Sharpening | Grinder |

7. Reduced Shank HSS Bits

These drill bits have a wider diameter and a reduced shank to fit your drill’s chuck. They are intended to drill holes larger than the width capacity of your chuck. For example, your chuck might have a 13 mm width limit, so a reduced shank bit can fit this while still having a drill diameter of 16 mm.

When drilling pilot holes, don’t exceed 25% of the reduced shank’s diameter. These drill bits are great for drilling wood, metal, and plastics.

Pros

- Increases hole diameter

- Fits standard drills

- Drills metal, wood, and plastic

Cons

- Only drills large holes

Product Specs

| Type | Twist Drill |

| Use | Wood, Metal, Plastic |

| Compatibility | Hand Drill, Power Drill, Electric Drill |

| Sharpening | Grinder, Oilstone, Drill Sharpener |

8. HSS Rivet Bits

These drill bits are designed for drilling small holes to insert rivets. They have fluted sides to increase the longevity of the bit. This means you can drill more holes before sharpening or replacing the bit.

The depth of the hole must not exceed 1.25 times the diameter of the hole. The drilled hole also needs to be larger than the rivet to allow for expansion and reduce the stress on the surrounding material.

Pros

- Fluted sides

- Long-lasting

- Specialist rivet drill

Cons

- Only drills small holes

- Only suitable for rivets

Product Specs

| Type | Twist Drill, Specialist |

| Use | Metal |

| Compatibility | Power Drill, Electric Drill, Hand Drill |

| Sharpening | Grinder, Diamond File, Oilstone |

9. Spade Bits

When you want to drill a large hole through wood, a spade bit is the right tool for the job. They have a ¼-inch hex shank for a more secure grip in the chuck, and a long spike with two spurs on either side for easier cutting. This brad point drill bit has a long reach, but it can reach even further with a shank extension attachment.

Spade bits typically range in diameter from 6 to 38 mm.

Pros

- Cuts large holes

- Suitable for wood

- Long reach

- Hex shank

Cons

- Can only cut wood

Product Specs

| Type | Flat-Bottom Boring Bits, Specialist |

| Use | Wood |

| Compatibility | Power Drill, Electric Drill, Hand Drill |

| Sharpening | Diamond File, Oilstone, Grinder |

10. Auger Bits

Auger drill bits are capable of drilling large holes in dry, thick, and hard lumber. They are distinguished by their large size. The shank is hexagonal for extra security in the drill chuck, and the screw-thread tip draws the drill into the material with minimal effort.

Auger drill bits have large flutes for removing the wood cuttings, while the single-spur cutting edge creates a wide, neat hole.

Pros

- Drills large holes

- Screw-thread tip

- Requires minimal effort

- Flutes remove lots of material as you drill

- Hexagonal shank for better grip

Cons

- Only suitable for large holes

Product Specs

| Type | Twist Drill, Specialist |

| Use | Wood |

| Compatibility | Hand Brace |

| Sharpening | Diamond File, Oilstone |

11. Forstner Bits

Benjamin Forstner invented this drill bit in 1874. They are commonly used for drilling holes for concealed hinges such as those found on kitchen cabinets. They range in size from 26 mm to 35 mm and are capable of drilling large-diameter holes in wood.

Two types are available:

- Sawtooth, which leaves a larger, rougher hole. They are better for drilling end grain.

- Continuous rim bits, which cut a smaller, neater hole.

Pros

- Drills large diameter holes

- Sawtooth and continuous rim bits

- Drills end grain

Cons

- Rough cut holes

- Not a precision tool

- Only suitable for wood

Product Specs

| Type | Flat-Bottom Boring Bits, Specialist |

| Use | Wood |

| Compatibility | Power Drill, Electric Drill, Hand Drill |

| Sharpening | Diamond File, Oilstone |

12. Countersink Bits

Countersink bits create beveled openings at the top edge of a pilot hole. They are available in 13 mm, 16 mm, and 19 mm diameters, and there are different types to drill metal and wood.

They are used alongside countersink screws and rivets to ensure they sit flush with the surface of the surrounding material.

Pros

- Creates beveled openings

- Neat finish

- Precise

- Drills metal and wood

Cons

- Specialist bits

Product Specs

| Type | Countersink Drill Bit, Specialist |

| Use | Wood, Metal |

| Compatibility | Power Drill, Hand Drill, Electric Drill |

| Sharpening | Cannot Be Sharpened |

13. Drill/Countersink Bits

This countersink bit is a fusion of an HSS drill bit and a countersink drill bit. It is positioned in the chuck via a small grub screw, which can be adjusted using an Allen key to achieve the desired length.

Drill/countersink bits are used for drilling pilot holes for countersunk screws and are available in two varieties: fluted or cross-hole. They are identified by the gauge of the screw they correspond to, such as 6G, 8G, and so on.

Pros

- Adjustable

- Fluted or cross-hole varieties

- Drills pilot holes

- Drills and countersinks at the same time

Cons

- Not cost-effective

- Only has one use

Product Specs

| Type | Countersink Drill Bit, Twist Drill, Specialist |

| Use | Wood |

| Compatibility | Power Drill, Routers |

| Sharpening | Cannot Be Sharpened |

14. Self-Centering Bits

Self-centering bits drill accurately centered holes for hinges in wood and other materials. The drill bit has a tip that sits in the countersunk hole, aligning itself with the center. When pressure is applied, the bit is released from the spring-loaded sleeve and works into the material.

Like a drill/countersink bit, the HSS bit in the sleeve can be removed by turning a grub bolt with an Allen key. Self-centering drill bits are categorized by the size of the screws they are designed to pre-drill.

Pros

- Precise

- Finds the center of the hole

- The HSS drill bit is removable

Cons

- Only has one purpose

Product Specs

| Type | Twist Drill, Specialist |

| Use | Wood |

| Compatibility | Hand Drill, Power Drill, Electric Drill |

| Sharpening | Grinder, Diamond File, Oilstone |

15. Spear Point (Glass and Tile) Bits

Spear point bits take their name from the shape of their tips. They are tungsten-tipped drill bits that specialize in drilling through glass and ceramic tiles. Spear points can also drill through porcelain pieces but they are unsuitable for toughened glass.

The diamond ground carbide tip shaves instead of cutting to create an accurate pilot hole. Spear point drill bits work at low speeds. You will also need a coolant such as water or kerosene to keep the blade moving smoothly.

You should never use a drill’s hammer setting with these bits or you will shatter the material. To achieve some extra purchase on the surface, you can apply tape to it to encourage the drill bit to penetrate the glass or ceramic.

You can also use this bit to drill stone, marble, or granite.

Pros

- Precision tool

- Diamond ground tip

- Drills pilot holes

- Suitable for glass and ceramics

- Drills stone, marble, and granite

Cons

- Requires coolant

- Cannot use a hammer drill

- Only suitable for slow speed settings

- Not suitable for toughened glass

Product Specs

| Type | Specialist, Countersink Drill Bit |

| Use | Glass, Ceramics, Tiles |

| Compatibility | Hand Drill, Electric Drill, Power Drill |

| Sharpening | Oilstone |

16. Diamond Tile Bit

This drill bit is intended for hard surfaces such as masonry and tiles, including porcelain. Start by holding the drill bit at a 45-degree angle, then ease the drill upwards as it starts to bite.

Like a spear point drill bit, you will need to set your drill’s speed to slow. You will also need to have some water to keep the bit and the material cool and increase the abrasion.

Pros

- Works on masonry and tiles

- Diamond-coated tip

- Hard wearing

Cons

- Difficult to master

- Works at slow speeds

Product Specs

| Type | Specialty, Counterbore Drill Bit |

| Use | Masonry, Ceramics, Tiles |

| Compatibility | Hand Drill, Electric Drill, Power Drill |

| Sharpening | Cannot Be Sharpened |

17. Special Direct System (SDS)

SDS drill bits are for drilling into dense materials such as masonry, concrete, and stone. They are very robust and work with your drill in rotary hammer mode. The shank has unique slots that allow for quick bit changes.

This bit takes its name from the German words steck, dreh, sitzi, which translate to mean stick, turn, seated. Over time, it has become universally known as the special direct system.

There are two types of SDS drill bits: SDS-Plus and SDS-Max. SDS-Max bits last longer, making them a better option for heavy-duty drilling work.

Pros

- Robust

- Long-lasting

- Suitable for heavy-duty drilling

Cons

- Only suitable for hammer mode

- Only used for masonry, concrete, and stone

Product Specs

| Type | Twist Drill, Specialist |

| Use | Masonry, Stone, Concrete |

| Compatibility | Power Drill, Hammer Drill |

| Sharpening | Grinder, Diamond File |

18. Step Drill Bit

Step drill bits have a conical body with stepped sides that resemble the outline of a Christmas tree. This is your go-to drill bit for making holes of multiple sizes with a single bit.

They can make holes in thin material, enlarge existing holes, and lightly burr. Step drill bits have a titanium-nitride coating that minimizes heat build-up and increases lubrication. Conical versions are also available without the stepped surface pattern.

Pros

- Creates holes of different sizes

- Titanium coated

- Great for thin material

- Enlarges existing holes

Cons

- Not for general use

- Specialist tool

Product Specs

| Type | Specialist, Countersink Drill Bit |

| Use | Metal, Wood, Sheet Materials |

| Compatibility | Hand Drill, Power Drill, Electric Drill |

| Sharpening | Cannot Be Sharpened |

19. Plug Cutting Bit

Plug cutters are excellent for hiding screw heads. One part of the drill bit cuts a hole with a countersunk base, while the other cuts a plug to the exact dimensions of the hole. This conceals the screw completely.

They are a favorite of cabinet makers and craftspeople who build high-end wooden products. To cut accurately, you should use a center press as these drill bits have no central point to steady them as you make your cut.

Pros

- Diamond-coated tip

- Ideal for cabinet making

- Countersinks

- Cuts plugs

Cons

- One specific use

- Difficult to master technique

- Needs a center point for accuracy

Product Specs

| Type | Specialist, Counterbore Drill Bit |

| Use | Wood, Sheet Material |

| Compatibility | Hand Drill, Power Drill, Electric Drill |

| Sharpening | Cannot Be Sharpened |

20. Saw Bit

Saw bits have a standard HSS drill bit tip, but the shaft of the bit is a cutting edge after the first 15 mm or so. As the drill bit bites into the material, the abrasive teeth give you the ability to cut laterally.

Drill bits work best with downward pressure on the tip, so working a saw drill bit sideways across the surface of your project can be difficult to control. This can create inaccurate holes if you aren’t experienced in using them.

Pros

- Cuts and drills

- Robust

Cons

- Difficult to control

- Might create inaccurate holes

Product Specs

| Type | Twist Drill, Specialist |

| Use | Wood, Sheet Material |

| Compatibility | Hand Drill, Power Drill, Electric Drill |

| Sharpening | Grinder, Diamond File, Oilstone |

Drill Bit Maintenance Tips

- Center punch the spot where you want to drill for more accurate drilling. This will prevent the bit from sliding over the surface when you turn it on.

- Find out the correct speed to use for each bit and material. Hard surfaces require a slower speed. Soft materials can be drilled at faster speeds.

- Apply the correct amount of pressure when drilling. With too much pressure, the drill might skew to one side or become broken. Using too little pressure means the drill bit won’t bite through the material.

- Store your drill bits in a dry location or moisture will eventually cause them to rust.

- Know what each drill bit is for. This means you won’t choose the wrong bit for the task.

- Know when you should and shouldn’t use the hammer action. Some drill bits will dull with prolonged hammer use, and some materials might break.

- Keep a jug of cold water nearby when you drill. Masonry bits get hot, so they need to be cooled regularly to avoid shortening their lifespan.

- Larger drill bits transfer considerable force to the drill. Make sure you have a tight grip.

- Apply pressure to the drill bit in a straight line. Always use downward or forward pressure.

- Make sure the drill bit is in the center of the chuck and straight.

- When drilling metal, apply lubrication fluid such as water or cutting fluid.

- Make sure the drill isn’t in reverse. If the bit spins the wrong way, it could overheat and dull.

- Clean your drill bits regularly during use. Removing any debris will prevent it from becoming trapped and causing the bit to overheat.

FAQs

Choosing a Bit

With the numerous drill bits to choose from, it can be difficult to decide on the right one for the job. Titanium nitride-coated drill bits are tough, but cobalt is tougher. Carbide drill bits are the strongest type but they are also the most expensive.

Consider the specific task you need the bit for when choosing one. This includes the material are you drilling and whether it requires a drill bit with strength, precision, or a specific task such as making holes for cabinet hinges.

If you will be using your drill for multiple big projects, you might need to hand-sharpen it at some point. Carbide-tipped and titanium nitride drill bits are excellent but could lose much of their effectiveness if you sharpen them.

If you aren’t worried about your budget, you can simply choose the strongest, most effective bits possible. In this case, that means buying a cobalt drill bit. They will endure sharpening because they are constructed from a steel alloy mixed with cobalt, rather than only having a special coating.