If you are a professional woodworker, you probably spend a lot of time working with a table saw. You might also make frequent use of a miter saw for more intricate work.

These tools are staples of any workshop. However, if you are relatively new to working with wood, it might be unclear which tasks they are suitable for and how to operate them.

In this article, we will look at the miter saw vs the table saw, the differences between the two, and why you might need to choose one over the other for a specific task.

Key Takeaways

- Table saws are great for large materials, rip cuts, and basic angles, while miter saws excel at precise angles, bevels, and complex projects.

- Table saws are versatile and powerful but can be dangerous, while miter saws are safer and more precise but limited to smaller pieces.

- A table saw is a good first choice for beginners learning woodworking, but a miter saw is better suited for carpenters and advanced projects.

- Both saws have their advantages and will be useful additions to any workshop, depending on the specific tasks and projects being worked on.

What is a Miter Saw?

Miter saws are power tools designed to make accurate angled cuts. They cut across the surface of your workpiece or along the edges, which is known as a bevel. A miter saw consists of a circular blade mounted on a pivoting arm. The arm typically swings to the left, unless you have a dual bevel miter saw, which can pivot in both directions.

What Is a Miter Saw Used For?

A miter saw offers numerous cutting options in the hands of an experienced user. It is ideal for cutting crown moldings, door frames, window frames, and picture frames. If something requires an angled cut, a miter saw is the right tool for the job.

A double bevel miter saw provides greater versatility and ease of use by allowing you to cut in both directions without turning over the piece you are working on. Even for an experienced carpenter, a double bevel saw will significantly speed up their work by reducing the amount of measuring and calculations that are required.

A miter saw is better suited to a carpenter than a woodworker. Carpentry involves working on-site and constructing parts of a home or public building. Carpenters work with various materials to make door and window frames with complex angles.

In contrast, woodworking involves making items from wood or composite materials, such as furniture and cabinets. Woodworkers typically work in factories or workshops to produce bespoke items and other pieces for the home or office.

Pros

- Increased accuracy

- Precise

- Cuts 45-degree angle cuts

- Makes bevel, miter, and compound cuts

- Safer to use than table saws

- Excellent versatility

- Ideal for small projects

Cons

- Unsuitable for cutting larger pieces

- Won’t make rip-cuts

What Is a Table Saw?

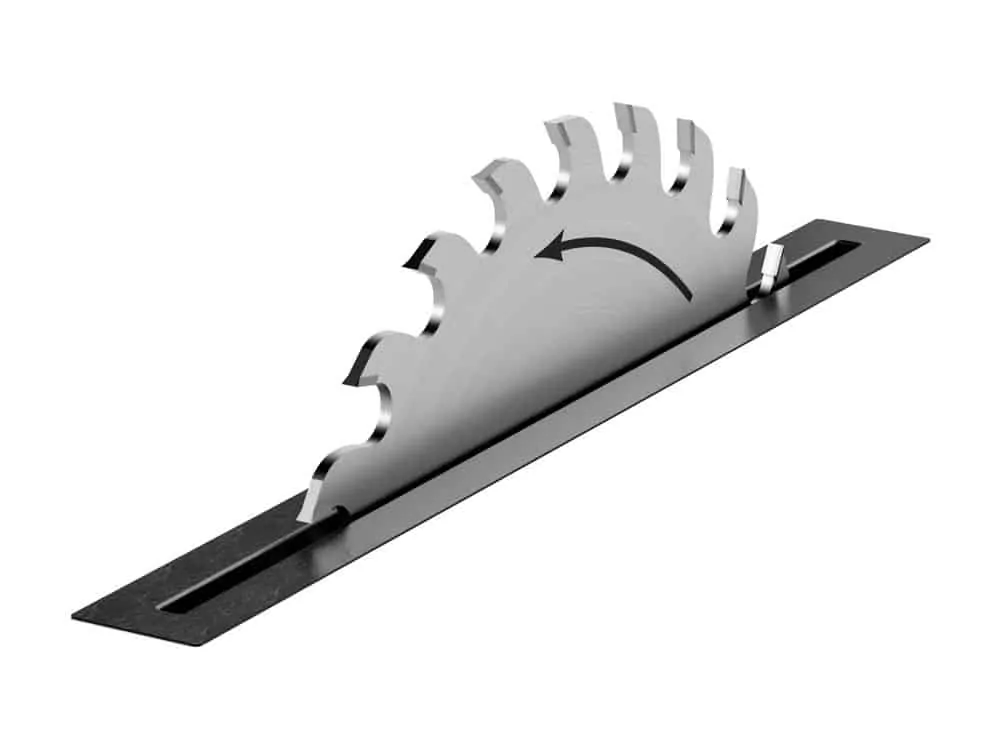

A table saw has a circular blade with an edge that rises through a slot in the center of a table. They often have miter gauges to help you cut basic 45-degree angles. The rip fence, located to the side of the blade, helps you make accurate rip cuts.

Most table saws, or bench saws as they are also known, are fixed in position, making them more suitable for workshop use. As cabinets and furniture are rarely made on-site, you will be able to easily cut their wooden components using a table saw.

It is possible to buy portable tabletop saws, but they are less useful due to their smaller size.

What Is a Table Saw Used For?

A table saw is a great all-around cutting tool. It is often referred to as the workhorse of the woodshop thanks to its versatility and cutting accuracy. It can speed up the woodworking process and is ideal for making rip-cuts, crosscuts, 45-degree-angle cuts, and working with large pieces of material.

If you have large panels or numerous pieces of wood to cut, a table saw will enable you to complete your work quickly without a loss of quality.

Can a Table Saw Cut Angles?

It is best to cut angles with a miter saw, but it is also possible to cut them using a table saw. If you don’t have a miter saw, the miter gauge on your table saw will also allow you to complete the job.

The miter gauge typically has a 60-degree swing to the left and right. To cut angles, clamp your stock to the miter gauge, and set your desired angle. Then, slide the wood towards the table saw blade, making sure it doesn’t move in the clamp.

There are other ways to cut angles with a table saw, such as using a jig assembly. However, the simplest way is to use the miter gauge on the saw.

Pros

- One of the most useful tools in a workshop

- Powerful

- Versatile

- Great for making rip cuts

- Ideal for working with larger materials

- Works well with sheet material

- The miter gauge allows you to cut basic angles

Cons

- Less accurate at precision cuts than a miter saw

- Large units are fixed in place

- Occupies a large area

- Dangerous to use

- Requires skill to make angled cuts

Can I Use a Miter Saw as a Table Saw?

It is difficult to use a miter saw as a table saw due to the differences in their designs. A table saw doesn’t restrict your workspace, so it is ideal for rip cuts and working with larger pieces of material.

A miter saw will cut accurate 90 and 45-degree angles, but only on smaller pieces. It has a pivoting arm directly behind the blade, which will get in the way of large pieces.

Miter saws can be used as an alternative to table saws but only for small pieces. For larger pieces or heavy workloads, it is better to use a table saw.

Is a Table Saw Better Than a Miter Saw?

Which saw is better will depend on the specific task. If you want a workhorse that can make light work of large stock, cut basic angles and make rip-cuts, then a table saw will be better.

However, if you want precision and accuracy while working on a complex project, then a miter saw is better. Miter saws are maneuverable, whereas most table saws are fixed in place in a workshop.

Should I Buy a Table Saw or a Miter Saw First?

If you are building your first workshop and aren’t sure which power saw to buy, a table saw is usually the best option. It will let you learn the basics of how a saw works and what it can do, and improve your skills. Once you are comfortable with that, you can graduate to using a miter saw.

Still, this isn’t a universal answer. Table saws are easier to use, but also more dangerous. A miter saw requires more skill to use precisely but is also safer.

The project you are undertaking will also determine which saw is better. Small and complex work requires a miter saw. Large sheet material, such as that used in cabinet making, will require a table saw.

Can You Use a Miter Saw on a Table?

Your miter saw will require a flat, secure surface to sit on. If you don’t have one, you risk inaccurate cuts. You can mount your miter saw to a small stand or table to make it a permanent fixture in your woodshop, especially if you use it frequently.

The only drawback of mounting your miter saw to a table is that it won’t be portable, but this won’t matter if you exclusively cut wood in your workshop.

Table Saw vs. Miter Saw Comparison Table

| Features | Table Saw | Miter Saw |

|---|---|---|

| Size | Occupies a lot of space | Takes up minimal space |

| Portability | Not portable at all | Can be transported to sites |

| Functionality | Multi-purpose cutting tool | Specialist saw for precise angles & bevels |

| Accuracy | Accurate if used properly | Known for extreme precision |

| Safety | Potentially dangerous | Very safe |

| Best For | Large material, rip cuts, cabinet and furniture making | Base or crown moldings, door & window frames, precision work |

| Skill Level | Beginner-friendly | Advanced |

FAQs

Table Saws or Miter Saws

Both saw types have merit and will make excellent additions to any workshop. If you frequently work with wood, at some point you will almost certainly have tasks that call for both types. A table saw will make short work of substantial pieces of material, while a miter saw will help you achieve a professional finish.

Whether you are a carpenter or woodworker, or both, the power of a table saw and the precision of a miter saw should both benefit you. If you are making a cabinet, you will be able to make accurate angled cuts and beveled edges with a miter saw.

At the same time, some carpentry jobs require numerous pieces to be cut relatively quickly. For quick, accurate cutting on a large scale, a table saw will be an excellent option.