At a glance, most miter saw blades look very similar: metal disks with teeth designed to cut or rip into materials. However, they vary greatly in terms of which materials they can cut and how well they perform.

There are countless miter saw blades to choose from, including some made by the leading names in power tools and sawing. While this means you will have plenty of options, it can also make it daunting trying to find the correct blade for a specific task.

To ensure you have the right blade for the job, we have reviewed seven of the best miter saw blades that are currently available. These blades were chosen for their material and size, how many teeth they have, and how wide a cut they make.

- Carbide-tipped blades

- Hook teeth

- Ultra-thin kerf

- Non-stick coating

- Carbide-tipped teeth

- Ultra-thin kerf

- Versatile two-pack

- Tungsten carbide-tipped

- Computer balanced

- Ideal for trim work

- Thin kerf reduces waste

- Great for veneer work

- Non-stick coating

- ATB tooth design

- Thin kerf

- Non-stick coating

- Triple-chip grind

- Thin kerf

- Non-stick coating

- C4 carbide-tipped

- Triple-ground teeth

Review Methodology: At Sensible Digs, we take pride in our thorough analysis and hands-on experience with a variety of miter saw blades. Our team of professionals has conducted extensive research, using a strict set of criteria to measure, test, and rank each product. We provide comprehensive reviews and scores based on data gathered through benchmark tests, tracking the performance of each blade. Our assessments evaluate key factors such as blade sharpness, durability, material, and cost-effectiveness. We also delve into design choices and their impact on user experience. Our findings are based on factual evidence, offering a trustworthy comparison of what sets each miter saw blade apart from its competitors.

The Best Miter Saw Blades of 2024

With so many miter saw blades to choose from, finding the right one for a specific job can be challenging. To narrow your search, we looked at numerous products before reviewing our seven best miter saw blades that are available today. We chose these blades for their material, size, teeth, and what they can cut.

Makita A-93681 10-Inch Miter Saw Blade

Best Miter Saw Blade for Hardwood

This Makita is a 10-inch blade, which makes it average-sized. Its 80 carbide teeth are honed using 600 grit to provide a very smooth finish that will help it cut through materials with less resistance.

The ultra-thin kerf helps you make smoother cuts with less stress on the motor and less material waste. The teeth are hooked at a 5-degree angle, with an alternative top and face design for precision cutting.

Another advantage of hook teeth is that they scoop the debris and sawdust out as you cut. This reduces the chances of blade gumming, which is one of the leading causes of dangerous kickbacks. Clearing the cutting line also means you will have a better view of what you are doing.

The only downside of this blade is its cost. It is a Bosch, so we wouldn’t expect it to be cheap, but other manufacturers offer packs of multiple blades for similar prices. Even so, this saw blade will slice through hardwood, softwood, and plyboard with ease and is an excellent choice if you are willing to spend some extra money.

Pros

- Carbide-tipped blade

- Hook teeth

- Ultra-thin kerf

- Fine crosscutting

Cons

- Expensive

Product Specs

| Kerf | Ultra-thin |

| Number of teeth | 80 |

| Max RPM | 5,870 |

| Suitable for | Hardwood, softwood, plyboard |

| Weight | 5 pounds |

| Size | 10 inches |

| Cost | $$ |

Our Ratings

User Experience

Freud D12100X100 ToothUltra Fine Saw Blade

Best Miter Saw Blade for Fine Woodworking

This Freud Diablo blade fits 12-inch miter saws, so it is ideal for cutting through thicker pieces of material. It has 100 teeth and an ultra-fine laser-cut kerf that will help make fine, accurate lines in various types of wood.

It is suitable for making accurate cuts at a range of angles and is an ideal blade to use for fine woodworking. Carbide-tipped teeth provide excellent heat resistance and overall durability.

Freud laser-cuts stabilizer vents to prevent sideways movement and decrease vibrations and noise. The surface has a Perma-Shield non-stick coating that ensures the blade glides through the material with minimum resistance, which also protects your miter saw’s motor.

These features add up to a smoother sawing experience while providing greater control and accuracy.

Pros

- Non-stick coating

- 12 inches

- Carbide-tipped teeth

- 100 teeth

- Ultra-thin kerf

Cons

- Expensive

- Only suitable for light woodworking

Product Specs

| Kerf | Ultra-thin |

| Number of teeth | 100 |

| Max RPM | 6,000 |

| Suitable for | Wood, wood composites |

| Weight | 2.54 pounds |

| Size | 12 inches |

| Cost | $$ |

Our Ratings

Personal Perspective

DeWALT 10-Inch General-Purpose Miter Saw Blade Set

Best All-Purpose Miter Saw Blade

This DeWALT product contains two miter saw blades. One has 60 teeth and is better for crosscutting, while the other is a general-purpose blade with 32 teeth. These blades are for 10-inch miter saws and have carbide-tipped teeth to increase their heat resistance and overall durability.

These blades cost half as much as some models from DeWALT’s competitors, yet they still come from a very reputable brand, so they offer excellent value for money. The 32-tooth blade is very versatile and will tackle the majority of your cutting tasks, whether you are working with wood, composite, plastic, sheet metal, or ply.

These DeWALT blades are computer balanced to reduce vibrations and noise and to improve your accuracy for a better finish. They will also fit sliding miter saws and their thin kerfs will help you make precise cuts every time.

Pros

- Excellent value for money

- Two-pack

- Very versatile

- Tungsten carbide-tipped

- Computer-balanced

Cons

- Durability issues.

Product Specs

| Kerf | Thin |

| Number of teeth | 32 + 60 |

| Max RPM | 6,000 |

| Suitable for | General-purpose |

| Weight | 3 pounds |

| Size | 10 inches |

| Cost | $ |

Our Ratings

Community Feedback

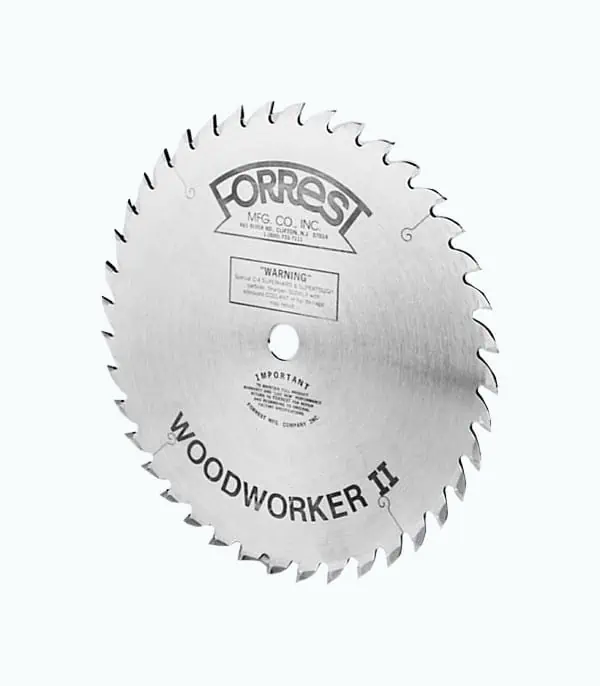

Forrest WW10407100 Woodworker II 40-Tooth Saw Blade

Best Miter Saw Blade for Trim and 2x4

Forrest provides some of the best-quality saw blades on the market and will help you make smooth, accurate cuts. This quality is reflected in its price, which is about as much as some budget miter saw units. It will probably only be a serious option for professionals or passionate hobbyists.

Despite having a 10-inch diameter, this blade slices to a maximum depth of two inches, which means it will cut through 2×4 with ease. The teeth are carbide-tipped, set at an angle of 15 degrees, and should cause far less splintering than inferior blades.

The kerf is thin and wastes very little material while cutting. It leaves a smooth edge without any additional sanding, which could speed up your work significantly.

Pros

- High quality

- Great for trim work

- Reduces wasted material

- Far less splintering

- Ideal for veneer work

Cons

- Very expensive

- Best suited to professionals

Product Specs

| Kerf | Thin |

| Number of teeth | 40 |

| Max RPM | 6,000 |

| Suitable for | General-purpose, trim, crosscutting, wood |

| Weight | 2 pounds |

| Size | 10 inches |

| Cost | $$$$ |

Our Ratings

First-Hand Impression

Freud Thin Kerf Sliding Compound Miter Saw Blade

Best Sliding Miter Saw Blade

This Freud blade has 72 teeth with a 5-degree negative hook, which improves the quality of the cut. It also utilizes the alternating top bevel design (ATB), meaning the teeth face left and right. This configuration pushes your workpiece down and toward the fence for improved control and accuracy.

The blade increases the performance of sliding miter saws, but it is also effective in standard saws when you want to perform crosscuts, rip cuts, or bevel cuts. The teeth are carbide-tipped for improved heat resistance and a longer lifespan.

The thin kerf helps you easily cut details with a sliding saw, which also reduces the strain on the saw’s motor. Like other Freud blades, this one is lubricated with a Perma-Shield non-stick surface to help it move through the stock smoothly.

Pros

- Non-stick coating

- ATB tooth design

- Thin kerf

- 72 teeth

- Designed for sliding miter saws

Cons

- Expensive

- Durability issues

Product Specs

| Kerf | Thin |

| Number of teeth | 72 |

| Max RPM | 6,000 |

| Suitable for | Sliding miter saws, general-purpose, trim, crosscutting, wood |

| Weight | 2.42 pounds |

| Size | 12 inches |

| Cost | $$$ |

Our Ratings

User Experience

Diablo D1080N Non-Ferrous Metal and Plastic Cutting Saw Blade

Best Miter Saw Blade for PVC

This Diablo blade is made specifically to cut non-ferrous metals and plastics, so it is ideal for working with PVC. The blade is 10 inches in diameter and has 80 carbide-tipped teeth. These teeth are in a triple-chip grind design at a 5-degree angle to provide a clean and burr-free finish.

In addition to pipes, this blade also cuts laminate, aluminum, and brass. This makes it a very versatile option if you are working on-site. It has a thin kerf, so it will leave a smooth cut and place minimal strain on the saw’s motor.

If you are worried about gumming and the increased risk of kickbacks that comes with it, this blade’s Perma-Shield will help. Perma-Shield is a non-stick coating that reduces friction and decreases how hard the motor has to work.

The teeth are carbide-tipped to enable them to withstand extreme heat during the cutting process and to protect the blades against dulling quickly.

Pros

- Non-stick coating

- 80 teeth

- Triple-chip grind

- Thin kerf

- Ideal for plastic and non-ferrous metal

Cons

- Expensive

- Quality issues.

Product Specs

| Kerf | Thin |

| Number of teeth | 80 |

| Max RPM | 7,000 |

| Suitable for | Plastic, brass, pipework, non-ferrous metals |

| Weight | 1.45 pounds |

| Size | 10 inches |

| Cost | $$$ |

Our Ratings

Personal Perspective

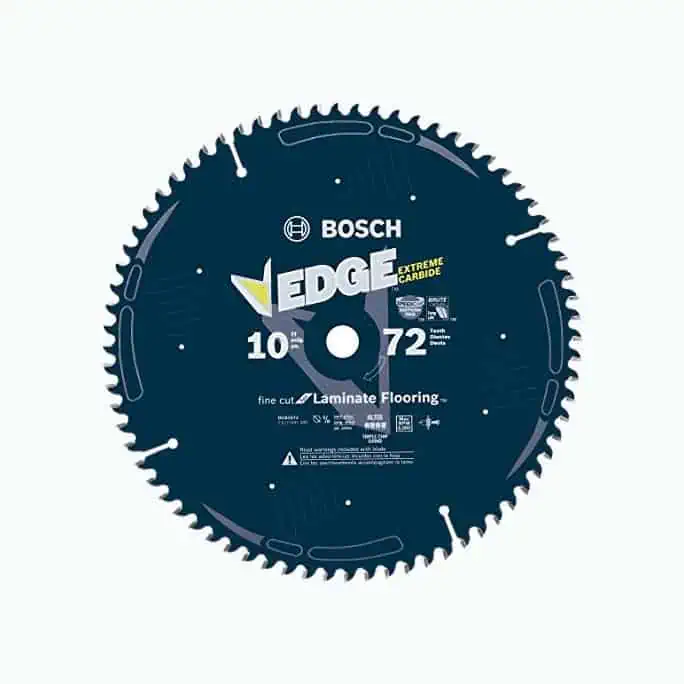

Bosch Edge DCB1072 Daredevil 10-Inch Laminate Saw Blade

Best Miter Saw Blade for Laminate Flooring

This Bosch blade will cut laminate flooring with ease. It has 72 teeth with a negative hook angle to eliminate chipping and extend the blade’s life.

Laminate is notoriously brittle, which is why Bosch has triple-ground the teeth to make them as sharp as possible, cutting the material rather than breaking it.

The teeth are tipped with C4 carbide to enhance their cutting power and longevity. These blades have an anti-friction coating to help them move through the stock smoothly. When combined with a thin kerf, this means a neater cut with less material wasted.

If you don’t need to cut laminate, this blade will also cut melamine, wood, plyboard, and other building materials, making it a versatile option to keep in your toolkit.

Pros

- Non-stick coating

- C4 carbide-tipped

- Triple-ground teeth

- Thin kerf

- Ideal for cutting laminate

Cons

- Expensive

Product Specs

| Kerf | Thin |

| Number of teeth | 72 |

| Max RPM | 6,000 |

| Suitable for | Laminate, melamine, wood, plyboard |

| Weight | 1.65 pounds |

| Size | 10 inches |

| Cost | $$$ |

Our Ratings

Community Feedback

| Product | Best | Kerf | No. of teeth | Max RPM | Suitable for | Weight | Size |

|---|---|---|---|---|---|---|---|

| Makita A-9368110 Miter Saw Blade | Hardwood | Ultra-thin | 80 | 5,870 | Hardwood, softwood, plyboard | 5 lbs | 10″ |

| Freud D12100X100 ToothUltra | Fine Woodworking | Ultra-thin | 100 | 6,000 | Wood, wood composites | 2.54 lbs | 12″ |

| DeWALT Miter Saw Blade Set | All-Purpose | Thin | 32 + 60 | 6,000 | General-purpose | 3 lbs | 10″ |

| Forrest WW10407100 Woodworker | Trim & 2×4 | Thin | 40 | 6,000 | General-purpose, trim, crosscutting, wood | 2 lbs | 10″ |

| Freud Thin Kerf Miter Saw Blade | Sliding Blade | Thin | 72 | 6,000 | Sliding miter saws, general-purpose, trim, crosscutting, wood | 2.42 lbs | 12″ |

| Diablo D1080N Non-Ferrous Blade | PVC | Thin | 80 | 7,000 | Plastic, brass, pipework, non-ferrous metals | 1.45 lbs | 10″ |

| Bosch Edge DCB1072 Daredevil | Laminate Flooring | Thin | 72 | 6,000 | Laminate, melamine, wood, plyboard | 1.65 lbs | 10″ |

When to Replace a Miter Saw Blade

Unfortunately, miter saw blades don’t have built-in indicators that tell you when they need to be replaced. As a result, you will need to know what to look for and keep an eye on your blade.

Before doing anything else, read your miter saw’s operating manual. This should provide an estimate of how often its blade will need to be replaced. Next, consider what you are sawing. If you are chopping through softwood, the blade will last longer than if you are cutting sheet metal or hardwood.

Another important consideration is the quality of the saw blade and its material. Carbon steel blades will dull faster than those made of cobalt steel or carbide-tipped tungsten.

You should pay attention to how effectively your saw cuts. If you notice that it is taking longer to cut the same materials that you were with previously, it is probably a sign that your saw blade is dull.

How quickly a blade dulls will obviously be influenced by how frequently it is used. If you use it every day, you should expect to replace it every two to four weeks. However, if you only use your miter saw occasionally, your blade could potentially cut well for years.

How to Choose a Miter Saw Blade

Choosing the right miter saw blade will help you make smooth, accurate cuts without damaging the material or your saw. On the other hand, the wrong blade can have the opposite effect. There are so many blades that you can spend a lot of time looking at them, but you can narrow them down by thinking about a few key points:

How to Clean and Maintain Your Miter Saw Blade

If you want to get as much use from your miter saw blade as possible, you will need to clean it occasionally.

- Place the blade in water: Once you have removed the blade from the saw, take some all-purpose cleaner and dilute it in warm water in a washing-up bowl. Submerge the blade in the water. Leave it to soak for a few minutes so the cleaner can do its work.

- Scrub: Carefully remove the blade and scrub away any stubborn deposits with a toothbrush. Submerge the blade in the water again, taking care to hold the blade by its center hole. Give it a gentle shake in the water to wash away any remaining bits of debris.

- Dry: Remove the blade from the water and dry it thoroughly with a clean cloth.

To keep the blade clean, you can lightly brush its surface after each use. This will remove any loose debris that could become compacted and cause damage later. One of the best ways to maintain your saw and blade is to apply oil and lubricant to the moving parts to ensure everything works smoothly.

Top Tip

How to Sharpen a Miter Saw Blade by Hand

It is possible to sharpen a miter saw blade using a power tool, which is much quicker. However, sharpening a saw blade only takes a maximum of about twenty minutes, even when using a file.

1. Unplug the Saw

Before you do anything else, make sure the saw is switched off and unplugged. Never attempt to remove the blade while the machine is plugged in.

2. Loosen the Wrench

Many miter saws have a fastening wrench. Simply loosen this to remove the blade.

3. Remove the Blade

Carefully remove the blade. Use a marker pen to mark the point on the blade where you will start sharpening. This is to prevent you from sharpening the same area twice. Next, clamp the blade in a vice, making sure the teeth are accessible.

4. Grab a File

Grab a triangular file. The teeth are set at a specific angle, so make sure you don’t deviate from this. Place the file on the start point where you marked the blade with the pen.

5. Zig-Zag the File

Move the file to match the angle of the teeth and work in a zig-zag motion, working backward and forward four times. Skip the next tooth and repeat the process for every other tooth.

6. Flip the Blade

Once you have done a full cycle, flip the blade and complete the same process on the teeth that face the other way, working toward your marker.

7. Clean the Blade

Remove the blade from the vice and clean it with some soapy water. Make sure the blade is completely dry before inserting it back into the saw.