Modern plumbing systems are designed to be as easy to assemble as possible. However, unless you are a trained plumber, you might not know which plumbing fittings are the best fit for the job.

There are countless plumbing fittings types, sizes, and materials to consider before you go to work. It’s easy to get intimidated but fittings aren’t as complicated as they might initially appear.

In this article, we will explain 20 types of plumbing fittings that you might encounter when undertaking DIY tasks. We will also describe the different materials you can find the fittings in and which jobs they should be used for.

Key Takeaways

- Adapters connect different sized pipes and can change a male pipe into a female, or vice versa.

- Nipple fittings connect pipes to appliances and are available in various materials such as brass, aluminum, and PVC.

- Union fittings connect two pipes and can be detached without damage, making them ideal for maintenance and replacements.

- Elbow fittings are curved and used to change the flow direction in pipes, commonly made with 45-degree or 90-degree angles.

Types of Plumbing Fittings

1. Adapter

An adapter has “male” and “female” ends. The male end has threads on the outside and the female has them on the inside so they can fit together.

They are used to connect pipes of different sizes and can even turn a male pipe into a female, or vice versa.

There are three types of adapters: male, female, and straight-threaded. If an end of the adapter has no threading, it needs to be welded or soldered onto the pipe.

Adapters are essential when extending or terminating pipe runs. Leak-free adapters can withstand high pressure and are commonly used in gas or water pipes. They also provide a smooth transition from piping to tubing systems.

You can find adapters in a variety of materials, including:

- Steel

- Aluminum

- Rubber

- Brass

- Copper

- Cast iron

- Polymers

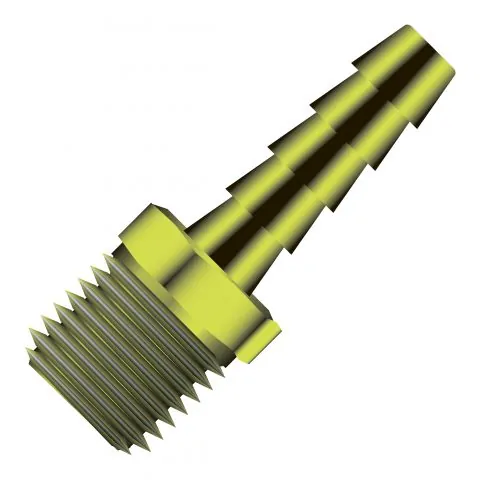

2. Nipple

A pipe nipple is one of the most popular types of fittings. It is also very important and connects pipes to appliances such as water heaters. It can connect two straight pipe runs.

The nipple fitting has two male ends and is available in various materials and finishes, including:

- Brass

- Aluminum

- Copper

- PVC

- Carbon steel

- Stainless steel

There are five main types of pipe nipples. They are:

- Weld nipple: Used to connect tube fittings. They are strong and can withstand extreme pressure surges, vibrations, and changes.

- Hexagon nipple: This has two threaded ends and a hexagonal center. Available in a variety of materials, lengths, and threads.

- Swage nipple: Used to transfer fluids from one pipe size to a different size.

- Barrel nipple: A short tubular nipple with an external taper thread at both ends, and is un-threaded between them.

- Close nipple: Threaded from end to end. Also referred to as a “running nipple”.

Before buying a pipe nipple, it is important to consider the material, thickness, and diameter to ensure you choose the correct fitting.

3. Union

Union fittings have three parts: a nut, a female end, and a male end. They are designed to connect two pipes in such a way that they can be detached without causing damage to them. They are used in maintenance and in situations where future replacements are likely.

Pipe unions are available in a wide range of durable materials such as:

- Cast iron

- Nickel

- Brass

- Bronze

- Plastic

- Rubber

One of the main advantages of union fittings is that they are easy to install.

They are used for various industrial and municipal settings such as process piping and wastewater systems. When buying a union fitting, consider which type and size you need.

4. Barb

Barb fittings usually have a male thread at one end and a tapered, ridged cone at the other. They are designed to grip the inside of a tube and seal the connection.

When the barb fitting is inserted, the hose or tube will expand and then relax. As the tube or hose returns to its original size, the connection is sealed and becomes difficult to undo. Barbed fittings are often used for gas, air, and fluid control applications in low pressure.

Plastic barbs are used for cold water connections. Brass barbs are used for hot water. Before buying a barb fitting, consider the following:

- Material compatibility

- Single or multi-barb

- Hardness of the tube or hose

- Inner diameter of the hose or tube

5. Coupling

Couplings are very similar to unions. However, they can’t be detached without damaging the pipes.

Couplings can be used to connect two pipes of the same size and diameter. They are also commonly used to move from one pipe size to another; a bell reducer is often used to do this as it connects a larger pipe to a smaller one.

You will find couplings with female threads or unthreaded. Unthreaded couplings are used with either copper soldering or plastic solvent welding.

There are two other common types of couplings:

- Compression: Connects two pipes using gaskets or rubber seals at both ends. The seals prevent leaking.

- Slip: Usually used to repair a specific length of damaged pipe.

Coupling fittings are available in a range of materials; including:

- ABS

- Chrome-plated brass

- Brass

- CPVC (chlorinated polyvinyl chloride)

- PVC

- Stainless steel

6. Cross

Crosses are four-way fittings, a combination of two tees (see below). They consist of one inlet and three outlets, and often have a solvent-welded socket or female-threaded ends.

Cross fittings are less popular than tees because they can stress pipes during temperature changes due to the four open ends.

Crosses are mostly used in plumbing systems where thermal expansion isn’t an issue, such as fire sprinkler systems.

Cross fittings are available in the following materials:

- Brass

- Steel

- Stainless steel

- Malleable

- PVC

7. Tees

Tees are three-way fittings. They look like couplings with an extra outlet in the middle. They are essentially short pipes with a 90-degree “branch” at the center.

There are two main types of tees:

- Straight tee: Used in setups where the main pipe is the same width as the tee branch.

- Reducing tee: Used when the tee branch is smaller than the main pipe.

Tees are available in a range of materials:

- ABS

- Chrome-plated brass

- Brass

- Copper

- CPVC

- PVC

- Stainless steel

8. Saddle Tee

Saddle tees are shaped similarly to a real saddle. They are only available in PVC and are used to add a tee to an existing pipe without needing to cut or re-solder it.

These are often used in irrigation systems when you need to add a new sprinkler line. Saddle tees are “snapped” onto the pipe using glue. Once the glue has set, a new hole is drilled.

9. Wyes

Wyes look like the letter “Y”. They are generally used in drainage fittings and have a 45-degree branch.

The angling of the branch is designed to reduce turbulence and friction. Wyes connect vertical drain pipes to horizontal ones.

Wye fittings are available in:

- ABS

- PVC

- Brass

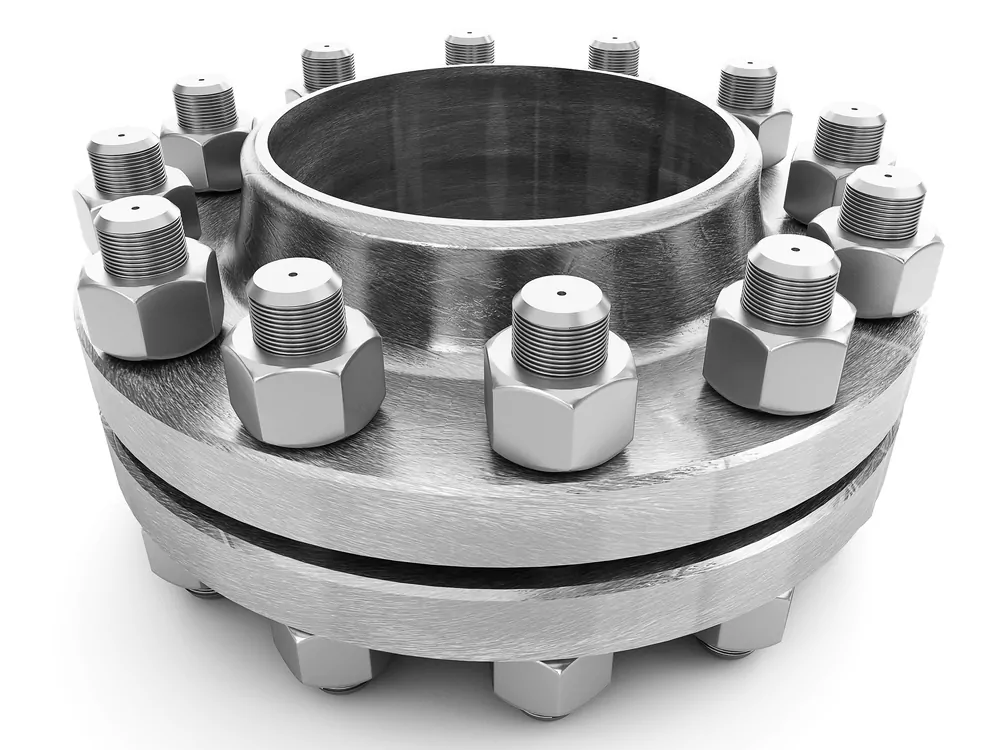

10. Flanges

A flange is a round fitting used to connect pipes. The pipes are either threaded or welded to the middle of the flange, and then sealed together. The holes on the outside are for bolts.

Flanges are mainly used for industrial applications due to their ability to withstand high pressure. You can also find flanges in residential pump systems.

In homes, PVC flanges are used when mounting toilets onto the floor. These are also referred to as “closet” flanges.

They are available in several materials, including:

- Copper

- Malleable

- PVC

- Brass

11. Elbows

Elbow fittings are curved and used to change flow direction. They are mostly made with 45-degree or 90-degree angles and can be sweated or threaded.

The ends of the elbow fitting can be designed for butt welding, threading, or socketing. A reducing elbow has two ends of different sizes to connect pipes with varying widths.

Elbows are made from these materials:

- Brass

- Chrome-plated brass

- CPVC

- Copper

- ABS

- PVC

- Stainless steel

12. Caps

Caps are used to seal the end of an open pipe and will contain liquid and gas. The cap can be attached to the pipe end with interior threading (female), or a solvent-welded socket.

The outside of a cap can be square, round, rectangular, I-shaped, or U-shaped; some will even have a handgrip.

Caps are available in a range of materials:

- ABS

- Copper

- CPVC

- Brass

- Chrome-plated brass

- PVC

- Malleable

- Stainless steel

13. Plugs

Plugs are used similarly to caps, but rather than being fitted over the end of a pipe, they are fitted inside. They are usually threaded to allow the plug to be removed in case the pipe is needed in the future.

They are available in many of the same materials as caps:

- ABS

- Copper

- Brass

- Stainless steel

14. Bushings

Bushings look like small screws. They are mainly used to connect pipes of different sizes, reducing a large fitting to a small pipe. They can be threaded on the inside and outside, but this isn’t always the case.

Bushing fittings are smaller than unions and couplings and are often used in similar situations.

This type of fitting is available in:

- Brass

- Chrome-plated brass

- CPVC

- Copper

- ABS

- PVC

- Malleable

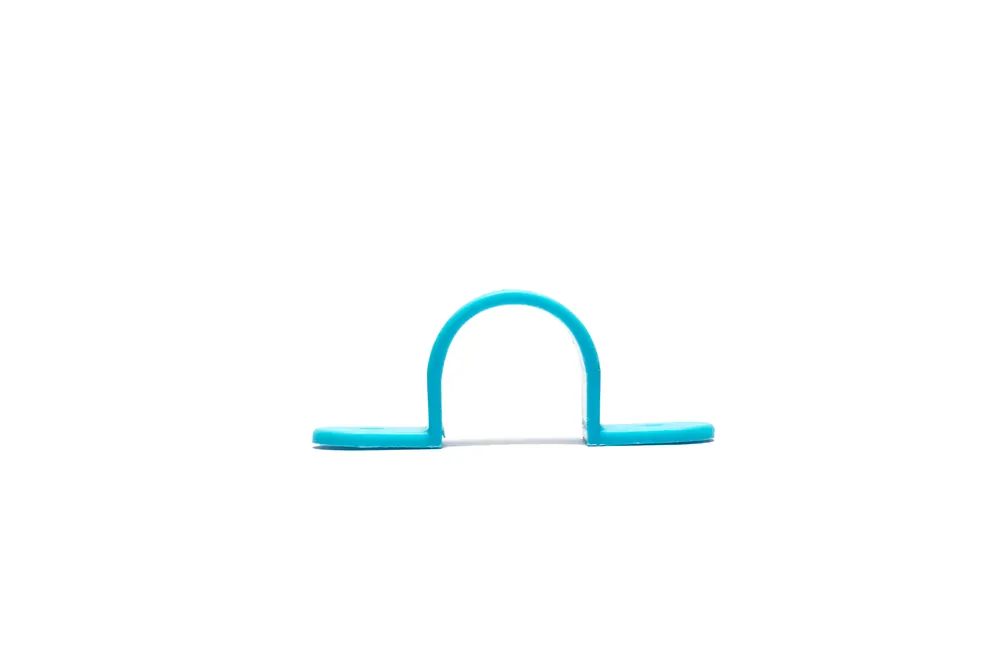

15. Mechanical Sleeve

A mechanical sleeve joins two pipes using a screw or piece and is easy to install.

The sleeve is usually made of rubber and is inserted into a stainless steel clamp. The clamp compresses the rubber, which creates a tight seal.

This type of fitting is slightly flexible and can be used to fix misalignments in awkward places.

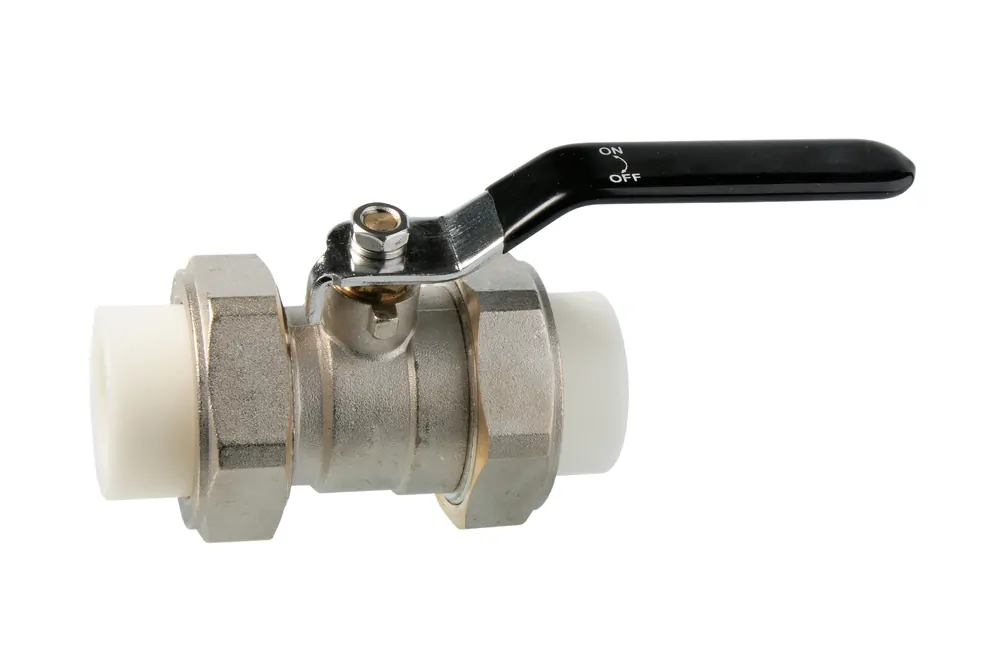

16. Valve

A valve is used to regulate or stop the flow of gas or liquid. Valves are usually categorized by their application, such as:

- Isolation: Used to disconnect a part of a piping system temporarily. Can be left open or closed, and can remain in place for years before needing replacement.

- Throttling: Used to control the pressure of a liquid. Designed to withstand stress, but they will eventually wear out. Usually installed alongside an isolation valve as an extra safety measure.

- Non-return: Also called check valves, these allow fluid to flow freely in one direction, but prevent reverse flow. Often used in sewage and drainage systems.

Valves are mainly made of metals such as:

- Bronze

- Cast iron

- Cast steel

- Stainless steel

- Carbon steel is used for high pressure or high temperatures

17. Reducer

A reducer is designed to reduce flow. It comes in two types:

- Concentric reducer: Looks similar to a cone. Designed to join two pipe sections on the same axis. Usually used when there is a change in pipe diameter.

- Eccentric reducer: Used in piping systems where the upstream pipe is larger than the downstream pipe.

Reducers are available in a range of materials such as:

- Carbon steel

- Alloy

- Stainless steel

18. Clean-Outs

A clean-out fitting has removable parts that enable access to drains without needing to remove the entire fitting. Clean-outs will allow an auger (a type of drill) to enter and clean a clogged drain.

It is important that clean-outs are placed in accessible locations to ensure you can reach them with an auger. Larger plumbing systems usually feature several clean-outs spread throughout the system.

Clean-outs are mostly made out of PVC.

19. Combo Tee

Combination tees have a gently curved central branch. They are used in drains to provide a smooth, slightly curving path and reduce the risk of clogging. The gentle curve also makes it easier for a plumber to push a snake tool through.

These fittings are available in PVC material.

20. Diverter Tee

A diverter tee is mainly used in pressurized hydronic heating systems. It diverts portions of the flow from the primary line into a side branch that is connected to a heat exchanger.

It is designed to allow a regular flow through the main line, even if the branch is shut off.

Installing a diverter tee can be challenging. It features directional marking that must be followed. If it’s installed backward, it won’t function properly.

Diverter tees are available in similar materials to standard tees:

- Stainless steel

- ABS

- Brass

- Chrome-plated brass

- Copper

- PVC

Plumbing Fittings Material Guide

Choosing the right material can be the difference between a watertight system and one that leaks. The most popular materials include:

- Cast-iron fittings: Can be used in DWV systems and are usually black.

- PVC schedule 40: Used in DWV systems, irrigation, and outdoor applications such as pools and sprinklers. The material can also be used in pressurized systems. It can’t be used with compressed gasses or air.

- PVC schedule 80: Can be used in pressurized systems. It is suitable for pressurized liquids, but not gasses or air.

- Copper: Used for hot and cold water distribution in pressurized systems.

- Acrylonitrile butadiene styrene (ABS): Commonly used in DWV systems in western parts of the United States.

- Brass: A mixture of metal alloys such as copper and zinc, brass is a common material for fittings. It is used in pressurized systems, mostly for hot water applications (1).

- CPVC (chlorinated polyvinyl chloride): Commonly used for drinking water at higher temperatures (up to 200 degrees). It can withstand higher temperatures than standard PVC (2).

Types of Pipes

Newer homes across the United States (built since the mid-1970s) usually have plastic pipes and fittings. The materials used are rated by the American Society for Testing and Materials.

Older homes (pre-1960) used cast iron or galvanized steel pipes for their drain, waste, and vent systems (DWV). DWV systems are designed to remove wastewater while preventing sewer gasses from entering homes.

Today, homes are fitted with PVC (polyvinyl chloride) and copper pipes. These materials are sturdy, durable, and easy to install (3). They also feature a range of plumbing connection types for ease of installation.