Circular saws are powerful cutting tools. They are ideal for cutting straight lines and, as they are handheld, there is no limit to the length of your cuts.

If you are a carpenter or any other type of woodworker, a circular saw will be an important addition to your tool collection. However, if you have never used one before, you might need some advice on how to do it effectively.

In this article, we will explain how to use a circular saw to make the most of its cutting power and accuracy. This includes learning the different parts of the saw, which cuts you can make, how to stay safe, and answers to some frequently asked questions.

Key Takeaways

- Wear safety goggles and a face mask for protection.

- Mark the cutting line clearly and use appropriate blade for material.

- Set blade depth to 0.25 inches below the material.

- Use two hands for control and let the saw work at its natural pace.

What Is a Circular Saw Used For?

Circular saws are powerful handheld cutting tools that have disk-shaped blades. They are used primarily for cutting long pieces of wood but can also cut other materials with the right blade. These materials include masonry, plastic, and even metal. As they are handheld tools, they are particularly useful on construction sites, enabling carpenters to make cuts wherever they are needed.

Circular saws are ideal for making crosscuts, rip cuts, and slicing through sheet material such as plywood. With enough experience, you will also be able to make miter and bevel cuts.

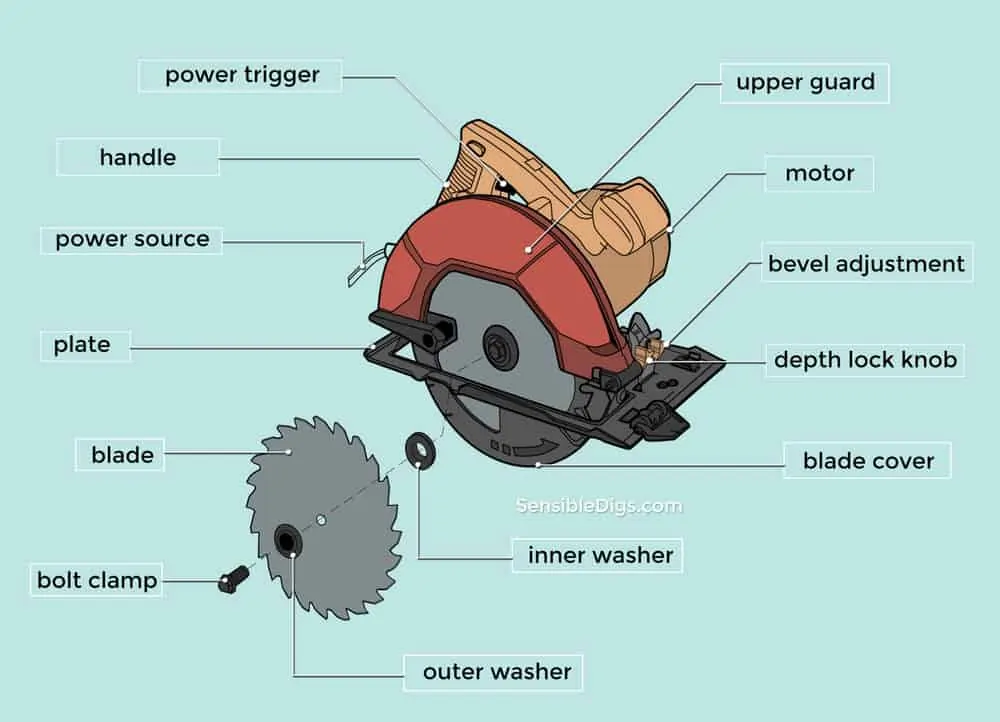

Parts of a Circular Saw

Before you start making cuts, you should take the time to familiarize yourself with the various parts of your circular saw:

Types of Cuts

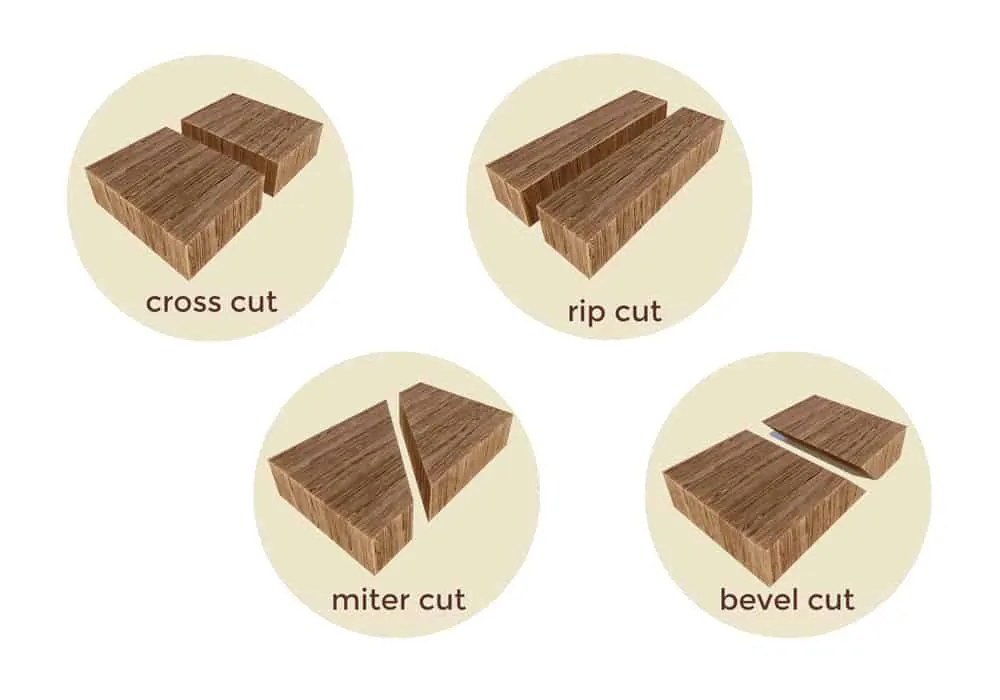

Circular saws are relatively simple tools but they are surprisingly versatile if you know how to use them. Here are the different cuts you can make with one:

Crosscut

A crosscut is when you cross across the grain of a piece of wood. This is used when you need to shorten a board by cutting it down to size, so it will probably be one of the cuts you make most often.

Rip Cut

A rip cut is made along the grain of the wood, splitting its fibers apart to make it narrower. Rip cuts are typically longer than crosscuts, which is why the freedom of movement of circular saws makes them an ideal choice.

Miter Cut

Miter cuts are made at an angle while keeping the blade vertical. This makes them ideal for cutting window frames or door frames, where you need pieces to fit together to surround the opening.

Bevel Cuts

In contrast to miter cuts, where the blade stays vertical, bevel cuts are made with the blade tilted. This is ideal for fitting two straight pieces together, such as when you are constructing wooden furniture.

How to Use a Circular Saw

Now that you are more familiar with circular saws and the cuts they can make, it is time to learn how to make those cuts. This step-by-step guide will show you how to use a circular saw to make a basic cut, which will give you a strong foundation before you move on to more advanced cuts.

You Will Need

Like any power tool, there is an element of danger when using a circular saw. Popular Mechanics magazine reports that about 30% of all saw accidents in Australia are caused by circular saws (1). However, you can minimize these risks by following safety tips and wearing protective gear.

Before you start cutting, make sure you have:

- Goggles

- An N95 face mask

- A circular saw

- A clamp

- Pencil or chalk

- A tape measure

- Dustpan and brush

- Vacuum cleaner if cutting indoors

1. Mark the Line

Like any sawing job, measure twice so you can cut once. Marking an accurate cutting line will remove any guesswork and give you a much better chance of achieving accurate results. Mark the line using a pencil or chalk.

Along the line you have marked, draw a few V shapes with the point meeting the line. This should help you cut more accurately.

2. Clamp the Material

Clamp the material in place securely. Otherwise, it could move while you’re sawing and ruin your cut.

3. Choose the Right Blade

You need to choose an appropriate blade for the material you are cutting. Wood blades have teeth like a standard saw, while blades for masonry and brittle materials have abrasive surfaces that use friction to slice through whatever they are cutting. Always use the right blade for a specific job, as this will protect your saw and improve the quality of your cuts.

4. Set the Depth

Once you have chosen the right blade for the task, set its depth to about 0.25 inches below the bottom of the stock you are cutting. This will ensure the blade exits the material smoothly and you get a clean cut.

5. Protect Yourself

You should now put on your safety goggles and N95 face mask to protect yourself against sawdust and flying debris. Circular saws are powerful cutting tools, which means there is a risk of pieces of material being launched as the blade exits the wood. As with any DIY task, it is better to be safe than sorry.

6. Line Up the Saw

Plug the saw in or attach its battery. Place the saw so the base plate is on the surface of the material, with the front of the blade lined up to the cutting line you marked. Don’t engage the motor yet but be sure to lift the blade guard out of the way.

7. Power Up

At this point, the blade should not be touching the workpiece but the base plate should. Press the trigger and wait for the blade to reach its optimal speed. Then, ease the saw forward slowly, applying consistent pressure.

8. Watch the Blade

Let the saw move at a speed it can handle. Don’t force it as this will place a strain on the motor and make the saw likelier to splinter the material. It might also increase the chances of a kickback occurring as the blade can’t move smoothly. Try to keep the blade on the scrap side of the cutting line you move it, so you don’t accidentally remove too much.

9. Power Off

When you reach the end of your cutting, release the trigger and allow the blade to come to a complete stop. Unplug the saw or remove its battery and sweep away any debris with your dustpan and brush. If you are indoors, you can use a vacuum to capture the finer sawdust. You can now remove your goggles and face mask to check your cut.

Circular Saw Tips

Circular saws are relatively easy tools to use but there are still some important tips that will help you achieve the best results. Here are some of the most helpful:

Good Side Down

If you want the best finish possible, have the good side of your material facing down while cutting. Circular saws tend to splinter the upper side of the wood and leave a neater cut underneath.

Use Masking Tape

A great way to reduce splintering is to apply a strip of masking tape to the wood before you mark your cutting line. The tape will prevent the blade from shearing the wood and help you achieve a neater finish.

Use the Fence

When cutting long sheets of plywood, use the short fence supplied with the saw. It will help you cut a straight line while working more quickly.

Learn Your Blades

Familiarize yourself with what each blade does and look at its teeth per inch, or TPI for short. You will get a good sense of which materials a blade can cut by looking at its tooth count. Blades with more teeth are suitable for harder materials and provide a neater finish, with the toughest materials requiring diamond grit rather than teeth.

A lower tooth count indicates that the blade is better for cutting softer wood and making rip cuts. If you want a general-purpose blade, look for a TPI somewhere in the middle.

Start Over

If the blade veers off the cutting line, don’t try to swing it back while sawing as you could overcompensate and steer too far the other way. This can end up doing far more damage.

Stop the saw and start over. This way, you will achieve a more accurate cut and also maintain control of the saw.

Set the Depth

Always set the blade depth before you start cutting. The bottom of the blade should be about a quarter-inch below the material you are cutting for the smoothest cuts possible.

Don’t Clamp the Off-Cut

Only clamp the wood you want to keep, not the part you won’t use, which is also known as the off-cut. This will allow the off-cut to fall away as the blade reaches the end of its cut, rather than holding it in place, which is known to cause kickbacks.

Use a Chalk Line

If you are cutting sheet material or other longer pieces, a chalk line will provide a quick marker that is very accurate.

Circular Saw Safety Tips

There are dangers when using a circular saw, like any power tool, so safety should always be at the front of your mind.

- Never change the blade while the saw is plugged in. Always disconnect it from the electrical outlet or remove its battery before trying to remove the blade.

- Use an appropriate blade for the material to prevent kickbacks.

- Make sure the blade is sharp. A dull blade will bind and cause kickbacks.

- Always wait for the blade to spin at full speed before bringing it into contact with the material.

- Wear safety goggles and an N95 face mask.

- Wait for the blade to stop turning before removing it from the material.

- Never touch the blade when the saw is connected to its power source.

- Don’t force the saw to move faster when cutting. This places a strain on the motor and could cause a kickback.

- Don’t wear loose clothing or jewelry when operating the saw.