Circular saws are powerful handheld tools that can quickly slice through sheet material. However, as effective as they are, even the best circular saw will be ineffective without a sharp, suitable blade.

There will be various circular saw blades to choose from, with different tooth counts that will make them effective for specific cutting tasks. If you haven’t purchased them before, you might need some help to find the best blade for your needs.

To help you choose the right product, we have reviewed seven of the best circular saw blades that are currently available. We chose these blades for their material, teeth per inch, kerf, and any protective coatings they have.

- Excellent general-purpose blade

- Carbide-tipped

- 60-tooth fine finish

- 5-degree hook teeth

- Carbide teeth

- 80 teeth per inch

- Micrograin formulation

- Triple-chip grind teeth

- Carbide teeth

- Anti-vibration vents

- Anti-kickback shoulder design

- Carbide-tipped teeth

- Perma-shield coating

- Laser-cut anti-vibration slots

- 60 teeth & thin kerf

- Carbide teeth

- Anti-kickback design

- Ideal for framing

- 120 teeth

- Slices through plywood

- Carbon steel

Review Methodology: At Sensible Digs, our hands-on experience and rigorous assessment of circular saw blades ensure we provide an accurate and professional evaluation of each product. We delve into the data, conducting in-depth analysis and comparative research, tracking performance and scoring based on key criteria. Our reviews measure the blade’s durability, cutting speed, material compatibility, and design features, which greatly affect user experience. We identify what sets top-performing blades apart from the rest and provide evidence-backed recommendations. Trust in Sensible Digs to guide you towards the best circular saw blade for your needs, based on our objective findings and reviews.

The Best Circular Saw Blades of 2024

Circular saw blades may all look similar at a glance but this basic shape can be used for various cutting jobs. To help you find the right one for your project, we have reviewed seven of the best circular saw blades you can buy today, chosen for their TPI, thickness, blade material, and durability.

DeWALT 10-Inch General-Purpose Circular Saw Blade Set

Best General-Purpose Circular Saw Blade

It is probably no surprise to find a DeWALT product on any of our lists. The company is known for its high quality and constant innovation, and this set gives you two blades for the price of one. It contains a 60-tooth cross-cutting blade and a 32-tooth general-purpose blade.

Each blade is computer balanced to reduce vibration and improve accuracy, which should result in a smoother finish. The tungsten carbide teeth stay sharper for longer because they resist heat, which frequently dulls lower-quality blades.

These slim-kerf blades will cut through hardwood, softwood, melamine, chipboard, and plywood. If you are looking for a versatile blade set that will be suitable for most of your cutting tasks, this DeWALT pair is a great choice.

Pros

- Comes in a pack of 2

- Excellent general-purpose blades

- Carbide-tipped

- 60-tooth fine finish blade

Cons

- Not the best quality carbide-tipped blades

Product Specs

| Weight | 3 pounds |

| Size (Inches) | 10 |

| Material | Tungsten carbide |

| Used for | General-purpose crosscutting |

| Total teeth | 32 and 60 |

| Max RPM | 6,000 |

| Price | $$ |

Our Ratings

User Experience

Makita A-03681 10-Inch Circular Saw Blade

Best Circular Saw Blade for Hardwood

This Makita blade is honed with 600 grit to give the teeth a mirror finish. The teeth are made of carbide, so they are heat-resistant and stay sharper for longer. The blade has 80 teeth per inch, so it is ideal for sawing through hardwood as well as plywood.

This high TPI means less tear-out and shredding, unlike other blades with fewer teeth. The ultra-thin kerf complements the 5-degree hook teeth. If you want to make fine cuts that don’t require any extra finishing, this blade will be ideal.

The other advantage of a thin kerf is less stress on the saw motor, which will protect your circular saw. You will also waste less material when cutting.

Pros

- 5-degree hook teeth

- Carbide teeth

- 80 teeth per inch

- Thin kerf

Cons

- Expensive

Product Specs

| Weight | 5 pounds |

| Size (Inches) | 10 |

| Material | Carbide |

| Used for | Hardwood |

| Total teeth | 80 |

| Max RPM | 5,870 |

| Price | $$$ |

Our Ratings

Personal Perspective

Bosch DCB1072CD Edge Circular Saw Blade

Best Circular Saw Blade for Medium-Density Fiberboard (MDF)

This Bosch saw blade can cut composite decking, so it will make short work of MDF and other soft materials. It has brute carbide teeth with upgraded C3/C4 micro grain formulation, which increases the blade’s durability and keeps it sharper for longer.

The teeth are a triple-chip grind, so they deliver a high-quality finish even when cutting abrasive materials. The thinner kerf provides a faster cut and places less strain on your saw’s motor.

The only downside is that this high quality comes at a price. It costs twice what you would pay for some multi-blade sets.

Pros

- Micrograin formulation

- Ideal for composite materials

- Triple-chip grind teeth

- Carbide teeth

Cons

- Expensive

Product Specs

| Weight | 1.82 pounds |

| Size (Inches) | 10 |

| Material | Carbide |

| Used for | Composites, MDF |

| Total teeth | 72 |

| Max RPM | 6,000 |

| Price | $$$ |

Our Ratings

Community Feedback

Irwin 7.5-Inch Metal Cutting Saw Blade

Best Circular Saw Blade for Metal

This Irwin blade is the result of cutting-edge design and state-of-the-art technology. It is laser-cut, with anti-vibration vents to prevent the blade from wobbling and ensure you make straighter cuts. The teeth contain a special carbide that can slice through steel and other non-ferrous metals.

This also means the teeth stay sharper for longer, even when you use them to cut through harder materials. Irwin utilizes an anti-kickback design on the shoulders to reduce the risk of accidents. The shape of the blade also creates less waste material and sparks.

This 68-tooth blade is designed with professionals in mind and is the ideal choice for all your metal-cutting needs.

Pros

- Anti-vibration vents

- 68 teeth

- Anti-kickback shoulder design

- Carbide-tipped teeth

Cons

- Expensive

- Best suited for sheet metal

Product Specs

| Weight | 13.8 ounces |

| Size (Inches) | 7.25 |

| Material | Carbide |

| Used for | Metal |

| Total teeth | 68 |

| Max RPM | 4,000 |

| Price | $$$ |

Our Ratings

First-Hand Impression

Freud 7.25-Inch Thin Kerf Circular Saw Blade

Best Circular Saw Blade for Melamine

This Freud blade employs a Hi-ATB tooth configuration with a thin kerf and 2-degree hook teeth to remove more debris and place less strain on the saw’s motor. It also has laser-cut, anti-vibration slots to reduce sideways movement and increase the blade’s accuracy and longevity.

Freud manufactures its own titanium cobalt carbide called TiCo high-density, which helps these blades crosscut more effectively. This blade has 60 teeth and is suitable for cutting melamine and other composite boards.

It won’t tear or shred the material as the blade slices through. To help it move through the material smoothly, it has a Perma-Shield non-stick coating that lubricates its surface.

Pros

- Perma-Shield coating

- Laser-cut anti-vibration slots

- 60 teeth

- Thin kerf

Cons

- Expensive

Product Specs

| Weight | 12 ounces |

| Size (Inches) | 7.25 |

| Material | Tungsten cobalt carbide |

| Used for | Melamine, plywood, laminates |

| Total teeth | 60 |

| Max RPM | 10,000 |

| Price | $$$ |

Our Ratings

User Experience

Oshlun SBW-080024 8-Inch Saw Blade

Best Value Circular Saw Blade

If you are looking for a high-performance blade but don’t want to pay premium prices, this is a great option. It is more of a general-purpose blade but also works well for framing.

It has 24 teeth, super-thin kerf, cooling vents, and expansion slots to prevent blade movement. It also has a unique anti-kickback design that makes it safer to use. This all adds up to an impressive blade, especially considering that it is much cheaper than some of the most expensive ones that we have looked at.

The teeth have an aggressive hook angle and are made of carbide to prevent overheating, which keeps them sharper for longer. This blade will cut through hardwood, softwood, particleboard, and plywood.

Pros

- Carbide teeth

- Anti-kickback design

- Excellent price

- Ideal for framing

Cons

- Quality issues

- Warps easily

Product Specs

| Weight | 8 ounces |

| Size (Inches) | 8 |

| Material | Carbide-tipped |

| Used for | General-purpose, framing |

| Total teeth | 24 |

| Max RPM | 7,500 |

| Price | $ |

Our Ratings

Personal Perspective

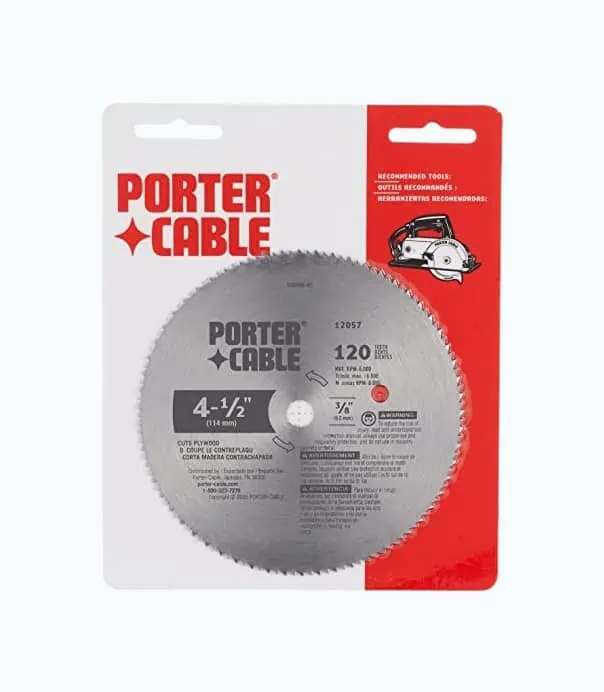

Porter-Cable 4.5-Inch Circular Saw Blade

Best Circular Saw Blade for Plywood

This Porter-Cable saw blade is an affordable option, costing much less than high-end Freud and Bosch blades. It has 120 teeth, so it is ideal for cutting plywood and veneers. It causes almost no shredding or tearing out, which means its finish will be extra-neat.

Plywood is notorious for shredding and splintering when cut, but this blade cuts so finely that you won’t need to worry about it. The blade is made of carbon steel, so you shouldn’t expect it to have the same lifespan as cobalt or carbide-tipped blades.

As the blade is carbon steel, overheating will also be an issue. Even so, for the price, this is a very effective saw blade.

Pros

- Excellent value for money

- 120 teeth

- Cuts plywood without splintering

- Carbon steel

Cons

- Cheaply made

- Dulls quickly

Product Specs

| Weight | 2.72 ounces |

| Size (Inches) | 4.5 |

| Material | Steel |

| Used for | Plywood, laminate |

| Total teeth | 120 |

| Max RPM | 7,500 |

| Price | $ |

Our Ratings

Community Feedback

| Product | Best | Weight | Size (Inch) | Material | Used for | Total teeth | Max RPM |

|---|---|---|---|---|---|---|---|

| DeWALT Circular Saw Blade Set | General-Purpose | 3 lbs | 10 | Tungsten carbide | General-purpose crosscutting | 32 & 60 | 6,000 |

| Makita A-03681 Circular Saw Blade | Hardwood | 5 lbs | 10 | Carbide | Hardwood | 80 | 5,870 |

| Bosch DCB1072CD Edge Blade | Medium-Density Fiberboard | 1.82 lbs | 10 | Carbide | Composites, MDF | 72 | 6,000 |

| Irwin Metal Cutting Saw Blade | Metal | 13.8 oz | 7 | Carbide | Metal | 68 | 4,000 |

| Freud Thin Kerf Circular Saw Blade | Melamine | 12 oz | 7.25 | Tungsten cobalt carbide | Melamine, plywood, laminates | 60 | 10,000 |

| Oshlun SBW-080024 8-Inch Saw Blade | Value For Money | 8 oz | 8 | Carbide-tipped | general-purpose, framing | 24 | 7,500 |

| Porter-Cable Circular Saw Blade | Plywood | 2.72 oz | 5 | Steel | Plywood, laminate | 120 | 7,500 |

Circular Saw Blade Types

There are various types of circular saw blades to choose from, each designed for specific purposes. The blade type will influence the number of teeth per inch and how they are arranged, which will have a significant impact on whether or not a blade is suitable for a particular task.

Flat Top Grind (FTG)

FTG blades have teeth that sit square to the saw plate. They cut through wood, much like a chisel. They rip the wood perpendicular to the grain, which means they won’t produce smooth cuts.

Pros

- Great for rip cuts

- Hard wearing

- Cuts quickly

Cons

- Only suitable for rip cuts

Alternate Top Bevel (ATB)

The teeth of an ATB blade point in alternating directions and they are designed primarily to shear wood. These are all-purpose blades that will be suitable for general cutting jobs.

Pros

- General-purpose cutting

- Very versatile

- Great for joinery

Cons

- Don’t excel in any area

- Not suitable for refined woodworking

High-Angle Alternative Bevel (HI-ATB)

These blades are a variation of the ATB design, with a different bevel angle. HI-ATB blades have a bevel angle of between 25 and 38 degrees, compared to 10 to 20 degrees for ATB blades.

High-angle blades are excellent for cutting veneers and other sheet-engineered wood used in cabinet making and bespoke furniture.

Pros

- Great for engineered wood

- Cuts smooth lines

- No chipping

- Suitable for laminate

Cons

- Fragile

- Prone to wear and tear

Triple-Chip Grind (TCG)

TCG blades have alternating chamfered and raker teeth. The chamfered teeth rough cut, while the raker teeth clean up the cut. This is the right blade to use for sawing plastic laminate and Corian, as well as non-ferrous metals such as brass and aluminum.

Pros

- Cuts a wide range of materials

- Makes neat cuts

Cons

- Better for materials other than wood

- Not for general cutting

How To Choose a Circular Saw Blade

There are several important factors to consider that will help you choose the right circular saw blade. Some of these elements might be more important than others, depending on the specific task you need the blade for.

Who Makes the Best Circular Saw Blades?

How To Change a Circular Saw Blade

1. Disconnect the Power

Before proceeding, make sure you disconnect the power supply from the wall socket or remove the saw’s battery.

2. Engage the Locking Mechanism

Press down on the arbor lock button, then rotate the blade until it engages the locking mechanism.

3. Use the Blade Wrench

Use the blade wrench to remove the arbor nut. To loosen the nut, turn the wrench in the same direction that the blade usually spins.

4. Retract the Blade Guard

Retract the blade guard and carefully remove the old blade. Even if the teeth aren’t cutting effectively, there will still be sharp edges that could injure you.

5. Insert the New Blade

Put the new blade onto the saw’s arbor, making sure the teeth are facing the correct way to cut effectively. There should be an arrow on the saw’s blade guard that will confirm whether or not you have inserted the blade properly.

6. Tighten the Arbor Nut

Tighten the arbor nut but be careful not to overtighten it. If you do, it will be far more difficult to loosen the next time you need to remove the blade.

You are now ready to plug your saw in and start using it.

How To Clean a Circular Saw Blade

Follow our guide to remove the blade. Once you have, place it in a bowl of warm soapy water. You can use detergent or an all-purpose cleaner if you prefer. Submerge the blade and leave it to soak for 5 to 10 minutes.

Grab a soft brush (an old toothbrush will work) and gently scrub any stubborn dirt or marks to remove them. Hold the blade by its center hole and gently shake it in the water to dislodge any remaining dirt.

Once the blade is clean, lift it out of the water and dry it with a soft, clean cloth. Make sure the blade is completely dry before you place it back into the saw or the moisture might cause corrosion and ultimately ruin your blade.

Again, follow our blade replacement guide to insert the blade back into the saw.