Bandsaws are powerful cutting tools with consistent movement in one direction that makes them invaluable to woodworkers. They have been used for centuries and remain an important part of any woodshop.

Like any power saw, a bandsaw is only as effective as its blade. At a glance, there might not be much difference between the various blades on the market, but it is important to choose the right one if you want your work to go smoothly.

To help you choose the best bandsaw blade for resawing, we have reviewed five of the most popular that are currently available. We chose these blades for their materials, types, and how many teeth per inch they have.

- Thin kerf

- Cuts at low tension

- Heat resistant

- Cobalt alloy steel

- Cuts quietly

- Reduced vibrations

- Three pack

- 65 to 67 on the Rockwell Hardness Scale

- Cobalt high-speed steel

- All-purpose blade

- Cuts hardwood and softwood

- Cuts mild steel & non-ferrous metals

- Great all-rounder

- Cuts awkward angles

- 64 to 66 on Rockwell Hardness Scale

Review Methodology: At Sensible Digs, we pride ourselves on conducting rigorous hands-on research and presenting data-driven reviews to help you make informed decisions. Our expertise in bandsaw blades is showcased through an in-depth analysis, where we evaluate various products from a user’s perspective. We compare and rank each blade based on key performance benchmarks such as resawing capacity, durability, sharpness, and ease of use. Our assessment focuses on factors that set the top blades apart, such as design choices and their effect on users. This evaluation is further backed by our professional experience and the results of stringent tests, ensuring you have the most reliable facts at your disposal. We strive to provide a comprehensive review, allowing you to choose the best bandsaw blade for resawing based on your specific needs.

The Best Resaw Bandsaw Blades of 2024

There are numerous bandsaw blades to choose from, which can make it difficult to choose the right blade for a specific task. To help you find the best bandsaw blade for resawing, we have reviewed five blades from some of the leading brands, chosen for their type, material, and teeth per inch.

Timber Wolf 1/4-Inch x 1/2-inch 6 TPI Bandsaw Blade

Best Carbide Bandsaw Blade for Resawing

This Timber Wolf blade is said to be able to cut 60% faster than standard thin kerf blades, thanks to its high silicon carbide steel material. It is ideal for resawing thicker stock and can cut under lower tension, which requires less horsepower from the saw.

Carbide also has the benefit of staying cooler for longer while cutting. This improves its durability, as heat is one of the main reasons that blades dull during use.

Timber Wolf makes excellent bandsaw blades, which is reflected in their price. Beginners might want to look elsewhere to save money but, if you have the budget, this is one of the best blades you will find.

Pros

- Thin kerf

- Ideal for thick stock

- Cuts under lower tension

- Excellent heat-resistance

Cons

- Expensive

Product Specs

| Weight | 1.5 ounces |

| Dimensions | 11.2 x 13.8 x 0.6 inches |

| TPI | 6 |

| Kerf | Thin |

| Price | $$$ |

Our Ratings

User Experience

Milwaukee 48-39-0511 44-7/8-inch 14-TPI Bandsaw Blade

Best High-Speed Bandsaw Blade for Resawing

This Milwaukee blade is high-speed steel and 8% cobalt to make it extremely durable. Its teeth are electron-beam welded to a special backing that ensures a long lifespan, dulling about three times slower than standard bandsaw blades.

The angles of the teeth and their deeper gullets also reduce the vibrations while cutting, which results in a smoother finish and less noise during use. Its relatively high TPI means this blade will also cut through metals such as aluminum, stainless steel, and even bronze.

Milwaukee states that its products are American-made, but they also say the blades are imported. It appears that the steel is Chinese, but the blades are assembled and welded in the United States, so both statements are true to an extent.

These blades are high quality and come in a pack of three, so they offer good value and mean you will have two spares when the first blade eventually dulls.

Pros

- Cobalt alloy steel

- Relatively quiet cutting

- Reduces vibrations

- Three-pack

Cons

- American-made, but imported steel

Product Specs

| Weight | 8.6 ounces |

| Dimensions | 19 x 6.9 x 0.2 inches |

| TPI | 14 |

| Kerf | Thin |

| Price | $$ |

Our Ratings

Personal Perspective

DeWALT 32-7/8-inch Portable BandSaw Blade

Best Portable Bandsaw Blade for Resawing

This DeWALT portable bandsaw blade set is made of 8% cobalt and high-speed steel. This gives it the heat resistance and overall durability needed to keep it sharper for longer.

The teeth score an impressive 65 to 67 on the Rockwell Hardness Scale, a sign that they won’t dull as quickly as carbon steel blades. This also means the blade can cut at high speeds for longer. It has an alloy steel back for greater strength.

This blade is suitable for cutting thick, medium, and thin gauge metals, thanks to its high tooth count and thin kerf. These DeWALT blades are reasonably priced but still score highly for customer satisfaction. As they are sold in a three-pack, they provide even better value for money.

Pros

- Reasonably priced

- Sold in a pack of three

- Scores 65 to 67 on the Rockwell Hardness Scale

- Cobalt high-speed steel

Cons

- Only suitable for portable bandsaws

Product Specs

| Weight | 5.6 ounces |

| Dimensions | 14 x 5.2 x 0.6 inches |

| TPI | 18 |

| Kerf | Thin |

| Price | $ |

Our Ratings

Community Feedback

Olson Saw FB14593DB HEFB 6-TPI Bandsaw Blade

Best for Resawing Hardwood

This is an Olson skip saw blade, which means it has a zero-degree rake angle and widely-spaced teeth. This also makes it a perfect tool for cutting through hardwood.

The benefit of a zero-degree rake is that the blade gums less while cutting because the teeth scoop out most of the debris and sawdust. This prevents the blade from overheating as quickly, which will keep it from dulling for longer. By removing debris, you will also have a clearer view of the cutting line, helping you achieve a neat finish.

This is an excellent all-purpose blade. It is affordable, allowing beginners and less experienced bandsaw users to get working without spending a lot of money. Despite its lower price, it will cut through hardwood and softwood, plastics, non-ferrous metals, and mild steel.

It is compatible with most stationary, floor-standing, and vertical two-wheel bandsaws.

Pros

- Great price

- Suitable for beginners and professionals

- All-purpose blade

- Cuts hard and softwood

- Cuts mild steel and non-ferrous metals

Cons

- Made abroad

- May vibrate a lot during use

Product Specs

| Weight | 1.76 ounces |

| Dimensions | 10.2 x 10.9 x 1.0 inches |

| TPI | 6 |

| Kerf | Medium |

| Price | $ |

Our Ratings

First-Hand Impression

Powertec 13117X 93-1/2-Inch Bandsaw Blade

Best Budget Bandsaw Blade for Resawing

This Powertec saw blade has a set of raker teeth that scoop the excess debris and sawdust away from the blade more efficiently. That means less friction and the blade staying cooler while cutting, which preserves its teeth for longer.

It has 10 teeth per inch, enabling it to neatly cut softwood and non-ferrous metals. It can also cut plastics and aluminum, with teeth that score 64 to 66 on the Rockwell Hardness Scale.

The blade is made of high-carbon steel, which provides an ultra-sharp cutting edge but dulls relatively quickly. While it can saw through hardwood, you should stick to softer materials if you want to preserve the blade for longer.

Carbon steel is flexible, so it is ideal for cutting awkward angles. It has far more flex than rigid cobalt and carbide steel blades.

Pros

- Excellent price

- Great all-rounder

- Ideal for beginners

- Cuts awkward angles

- 64 to 66 on the Rockwell Hardness Scale

Cons

- Carbon steel dulls quickly

- Best suited for softer materials

- Some welding issues

Product Specs

| Weight | 1.6 ounces |

| Dimensions | 10 x 10 x 1 inches |

| TPI | 10 |

| Kerf | Thin |

| Price | $ |

Our Ratings

User Experience

| Product | Best | Weight | Dimensions | TPI | Kerf |

|---|---|---|---|---|---|

| Timber Wolf 6 TPI Bandsaw Blade | Carbide Blade | 1.5 oz | 11.2 x 13.8 x 0.6″ | 6 | Thin |

| Milwaukee 48-39-0511 14-TPI Blade | High-Speed | 8.6 oz | 19 x 6.9 x 0.2″ | 14 | Thin |

| DeWALT 32-7/8-inch BandSaw Blade | Portable | 5.6 oz | 14 x 5.2 x 0.6″ | 18 | Thin |

| Olson Saw FB14593DB HEFB Blade | Hardwood | 1.76 oz | 10.2 x 10.9 x 1.0″ | 6 | Medium |

| Powertec 13117X Bandsaw Blade | Budget Pick | 1.6 oz | 10 x 10 x 1″ | 10 | Thin |

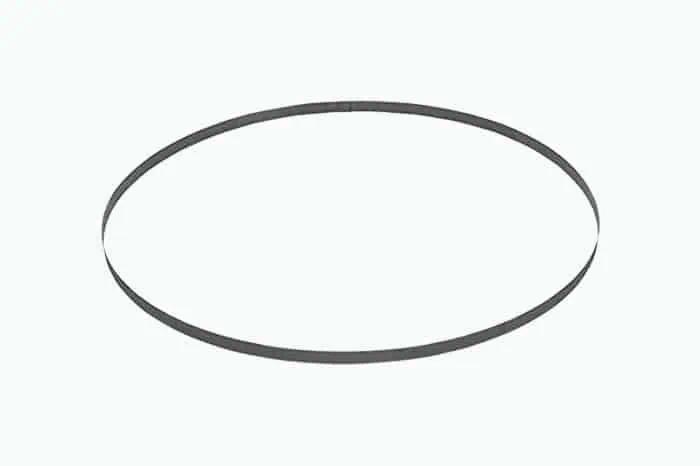

What is a Resaw Bandsaw Blade?

A resaw bandsaw blade allows you to make cuts along the grain to create boards or veneers. Resaw blades are usually wider than standard blades, typically 2 to 3 inches, and have a small kerf to reduce the amount of wood that is wasted. The kerf is the slit created when the saw cuts through the material.

Resaw blades cut straighter and have less flexibility than standard bandsaw blades. This reduces the amount of bowing when the stock passes through the blade. Resaw blades need to be tensioned correctly to ensure the blade deflects no more than 0.25 inches when pressed in the middle. The pre-tensioning of the blade ensures it will provide a neat, accurate cutting line.

How to Choose a Resaw Bandsaw Blade

There are various factors you need to consider if you want a reliable, accurate resaw bandsaw blade:

How Do You Set a Bandsaw to Resaw?

Bandsaws are excellent tools but if you want to use one to resaw materials, it is important to know how to set it up properly.

1. Choose the Right Blade

Like any sawing task, it is important to choose a suitable blade for the job. If you are resawing boards and want to remove debris while cutting, choose a blade with a lower tooth count and deep gullets. Resawing typically requires a saw blade that is thicker and will reliably cut a straight line.

Remember

2. Tension the Blade

The correct blade tension will keep your stock centered and provide better control. It also prevents the blade from flexing, which could otherwise cause issues if you need to make precise cuts and potentially even become dangerous.

With the saw unplugged, install the blade using lateral guides, with the thrust bearing opened and backed off. Make sure this is done above and below the table, checking that they are not in contact with the blade. You can now safely tension the blade.

Top Tip

3. Adjust the Blade Guides

With the saw blade tensioned correctly, close the wheel covers and power up the saw. This will let you see how the blade tracks and adjust its speed to see how it behaves at full throttle before you proceed. Adjust the tracking as necessary while monitoring the blade.

If the blade starts to vibrate, increase or decrease the tension slightly until it stops vibrating. Once you achieve the correct tension, you should hear a change in how the saw sounds. Preventing the saw from flexing unintentionally will also help you make neater cuts.

4. Lateral Blade Guides and Thrust Bearings

Now that the blade is tensioned correctly and running smoothly, switch off the machine. Move the thrust bearings and lateral blade guides close to the blade. Make sure they are snug as this will help guide the blade while cutting.

You can now switch the machine back on and start resawing stock.